|

FYI - A-1 Miller's Performance Enterprises is a legal, legitimate, tax paying and reputable business. And as of 2024, A-1 Miller's Performance Enterprises is still in business and offering all parts and services listed in this website. Please click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, if you need a part or parts, or service(s) performed that's not listed or mentioned in this website, and/or for FREE professional and honest technical customer service assistance and support and payment options. |

How

to Weight a Competition Garden Pulling Tractor (so it will pull better)

How

to Weight a Competition Garden Pulling Tractor (so it will pull better)

Inspiring Small Engine, Lawn & Garden, and Garden Pulling Tractor

Enthusiasts Since 1996. Where Science and Common Sense Come Together for

Safety and Improved Engine/Tractor Performance

A-1 Miller's Performance Enterprises

- Parts & Services Online Catalog

This page was last updated 12/30/17. (Click Refresh to see changes or updates.) Optimized for 1024 x 768 screen resolution. To search for a word or phrase in any of my web sites, press CTRL and F to open the Find dialog box in your web browser.

NEW! A-1 Miller's Professional Automotive Engine Rebuilding and Modification Services. And Build You a Competitive Mini Pulling Truck and Big Wheel Mini Rod Pulling Tractor. Chevrolet, GMC, Chrysler, Ford, Diesel engines, etc. More details and information coming later.

There's a cheater in every sport, and competition tractor

pulling is no different. Honest pullers who ignore the cheater(s) are fools.

And when there's prize money involved, a fool and their money are soon parted.

Anyway, to make competition pulling a fun and fair sport for the entire family,

while at the pulls, keep an eye on your competition's tractors. It's been

known that certain disgruntled pullers (cheaters or

sore losers

There's a cheater in every sport, and competition tractor

pulling is no different. Honest pullers who ignore the cheater(s) are fools.

And when there's prize money involved, a fool and their money are soon parted.

Anyway, to make competition pulling a fun and fair sport for the entire family,

while at the pulls, keep an eye on your competition's tractors. It's been

known that certain disgruntled pullers (cheaters or

sore losers  ) belonging

to various associations/clubs, virtually anywhere and everywhere, will, while

on the weighing scale at the pull sites, have been known to remove ballast

weights from their own pulling tractor to get the tractor's (with driver)

weight down to a specified weight limit for any particular class, then when

nobody is watching the scales, or looking after the tractor leaves the scales,

the [owner or operator of the tractor] will place the (removed) weight(s)

back on the tractor. This is why it's important that when at the pulls, it's

best to appoint (by the [honest] president) or vote-in (by the pullers) a

trusting and honest "designated scale watcher" person in a pulling club or

association to keep an eye on the pulling tractors/vehicles while on the

scales, and especially when they leave the scales and when they park their

tractors while they're waiting their turn to pull. Because nobody likes a

cheater. All a cheater needs is an opportunity in an attempt to gain an advantage

on the track. This is also the fastest way for a pulling association or club

to gain a bad reputation and lose honest pullers. (Bad news travels fast.)

This type of behavior doesn't happen often, but you need to be prepared if

or when it does happen. But then again, if the winning tractor is

suspected of cheating on the track (illegal fuel, engine, weight, etc.),

there's always the protest rule. But only if it's enforced by the pulling

association. Remember - cheating is devious theft with a sly smirk.

Heck, some pulling associations/clubs vote-in and/or change certain rules

in a meeting during the off-season, lock them in for several years, but don't

even enforce or follow their own rules during the pulling season! They change

their rules so often, they might as well just write them in pencil! Another

thing I don't understand is when a [prominent] puller of an association/club

ask the president of the club if an illegal part can be used in his engine

for pulling, and the president says, "yeah, sure!" But the pulling

association/club's sanctioning rules, the very same rules that the members

(pullers) of the association/club discussed about and voted-on in a meeting,

clearly states in black and white that such a part cannot be used.

) belonging

to various associations/clubs, virtually anywhere and everywhere, will, while

on the weighing scale at the pull sites, have been known to remove ballast

weights from their own pulling tractor to get the tractor's (with driver)

weight down to a specified weight limit for any particular class, then when

nobody is watching the scales, or looking after the tractor leaves the scales,

the [owner or operator of the tractor] will place the (removed) weight(s)

back on the tractor. This is why it's important that when at the pulls, it's

best to appoint (by the [honest] president) or vote-in (by the pullers) a

trusting and honest "designated scale watcher" person in a pulling club or

association to keep an eye on the pulling tractors/vehicles while on the

scales, and especially when they leave the scales and when they park their

tractors while they're waiting their turn to pull. Because nobody likes a

cheater. All a cheater needs is an opportunity in an attempt to gain an advantage

on the track. This is also the fastest way for a pulling association or club

to gain a bad reputation and lose honest pullers. (Bad news travels fast.)

This type of behavior doesn't happen often, but you need to be prepared if

or when it does happen. But then again, if the winning tractor is

suspected of cheating on the track (illegal fuel, engine, weight, etc.),

there's always the protest rule. But only if it's enforced by the pulling

association. Remember - cheating is devious theft with a sly smirk.

Heck, some pulling associations/clubs vote-in and/or change certain rules

in a meeting during the off-season, lock them in for several years, but don't

even enforce or follow their own rules during the pulling season! They change

their rules so often, they might as well just write them in pencil! Another

thing I don't understand is when a [prominent] puller of an association/club

ask the president of the club if an illegal part can be used in his engine

for pulling, and the president says, "yeah, sure!" But the pulling

association/club's sanctioning rules, the very same rules that the members

(pullers) of the association/club discussed about and voted-on in a meeting,

clearly states in black and white that such a part cannot be used.

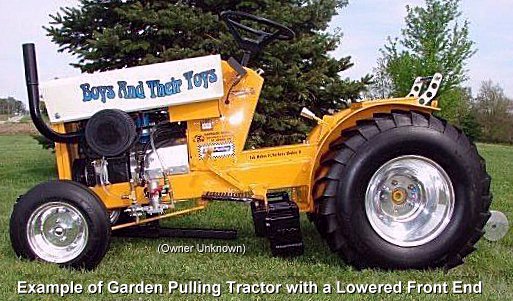

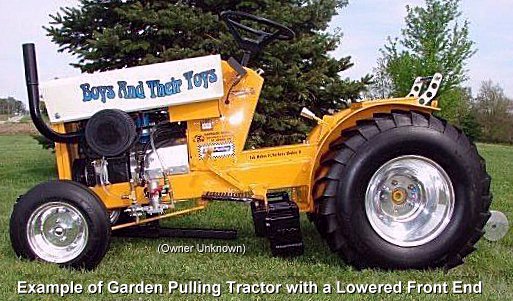

The rule of thumb for ALL pulling

tractors is to get the front end as low as possible for better weight

distribution and leverage. By doing this, the rear of the tractor and with

a 13" hitch height, the drawbar is higher than the centerline of the rear

axles. When the progressive weight of the sled begins to place pressure on

the drawbar, this will make it harder to raise the front end of the tractor,

allowing the tread on the rear tires to grip the ground more.

(Newton's third law of motion.) To lower the front of the

tractor, either install small diameter tires on the front axle and/or install

lowered or reversed spindles. Use your best judgment because there is no

exact percentage or inches of rake of how much the front end should be lowered.

Just make sure that any part of the front of the tractor don't drag the ground,

especially the extended weight bar.

The rule of thumb for ALL pulling

tractors is to get the front end as low as possible for better weight

distribution and leverage. By doing this, the rear of the tractor and with

a 13" hitch height, the drawbar is higher than the centerline of the rear

axles. When the progressive weight of the sled begins to place pressure on

the drawbar, this will make it harder to raise the front end of the tractor,

allowing the tread on the rear tires to grip the ground more.

(Newton's third law of motion.) To lower the front of the

tractor, either install small diameter tires on the front axle and/or install

lowered or reversed spindles. Use your best judgment because there is no

exact percentage or inches of rake of how much the front end should be lowered.

Just make sure that any part of the front of the tractor don't drag the ground,

especially the extended weight bar.

The best place to position weights is towards the front of the tractor on an extension and underneath the transaxle, for a lower center of gravity, so the tractor won't go from side to side down the track as much. If the weights are positioned high on the tractor, that would make it top heavy, causing it to go from side to side down the tractor, especially high speed tractors. Weights mounted high have no effect on slower pulling tractors.

The same thing here applies to the big pulling tractors as well. All pulling tractors need to avoid using wheel weights and place the majority of the weight under the tractor for a lower center of gravity for better stability of the tractor while going down the track.

A pulling tractor will pull

best when most of its weight is on the rear tires

and the front tires barely make contact on the track. To "balance the tractor"

for various to track conditions, weight may need to be "juggled" from front

to rear and vice-versa. On a hard, dry or loose track, weight will need to

be removed from the front of a tractor placed at the rear (and you'll need

to pull in a slightly faster

gear). And on a moistened

or "biting" track, weight will need to be removed from the rear of a tractor

and placed on the front (and you'll need to pull in a slightly slower

gear).

A pulling tractor will pull

best when most of its weight is on the rear tires

and the front tires barely make contact on the track. To "balance the tractor"

for various to track conditions, weight may need to be "juggled" from front

to rear and vice-versa. On a hard, dry or loose track, weight will need to

be removed from the front of a tractor placed at the rear (and you'll need

to pull in a slightly faster

gear). And on a moistened

or "biting" track, weight will need to be removed from the rear of a tractor

and placed on the front (and you'll need to pull in a slightly slower

gear).

"Balancing" a pulling tractor greatly depends on which class the tractor pulls in. A stock tractor will not balance like a highly modified and vice-versa. In the stock class(es), a tractor require more weight toward the front because the rear tires turns slower, causing them to dig in more, which will cause the front of the tractor to raise easier. But as you move up in the classes, when the tractor has a more powerful engine and more ground speed, the tractor will need less weight on the front and more on the rear because due to the increase in engine torque, the tires want to break traction easier.

The weights need to be "juggled" so there'll be adequate weight on the rear tires for traction and sufficient amount of weight on the front of the tractor to hold the front end down. But then again, you want the front tires to barely skim on the surface. This places about 90-95% of the weight on the rear tires for most traction. You can also use your upper body weight to lean forward, backward and to either side to guide the tractor straight down the track.

To reduce weight on a garden pulling tractor, remove all starting

mechanisms, install a small

motorcycle battery or a small, lightweight and rechargeable

12 volt sealed lead acid (SLA) battery with a minimum 4AH

(Amp Hour) rating on the tractor, use a machined billet aluminum starter

pulley on the crankshaft PTO end, then use a 2 wheel remote starter cart

with an automotive or tractor starter motor with a V-belt pulley, high amperage

push-button [starter] switch and an automotive 12 volt battery motor to crank

the engine to start it. The battery on the tractor is used to power the ignition

and/or electric fuel pump only. And with no charging system, a remote

battery charger will need to be used to keep the battery

fully charged when the tractor and starter cart are not in use. Also, keep

in mind if using a high-output/performance coil, because these draw more

amps from the battery. The average life expectancy of most standby batteries

is between 3-5 years.

To reduce weight on a garden pulling tractor, remove all starting

mechanisms, install a small

motorcycle battery or a small, lightweight and rechargeable

12 volt sealed lead acid (SLA) battery with a minimum 4AH

(Amp Hour) rating on the tractor, use a machined billet aluminum starter

pulley on the crankshaft PTO end, then use a 2 wheel remote starter cart

with an automotive or tractor starter motor with a V-belt pulley, high amperage

push-button [starter] switch and an automotive 12 volt battery motor to crank

the engine to start it. The battery on the tractor is used to power the ignition

and/or electric fuel pump only. And with no charging system, a remote

battery charger will need to be used to keep the battery

fully charged when the tractor and starter cart are not in use. Also, keep

in mind if using a high-output/performance coil, because these draw more

amps from the battery. The average life expectancy of most standby batteries

is between 3-5 years.

All starter carts crank the engine from the right side of the tractor, when sitting on the tractor. All Ford tractor starter motors turn clockwise when facing the shaft, and 99% of all small gas engines also turn clockwise when facing the flywheel. So make sure that the starter is installed so it'll turn the same direction as the engine. Position the starter motor on the cart as shown here, with the shaft facing your left when standing behind the cart. But if you have a different type of starter motor on a starter cart that rotates in reverse of normal engine rotation, then the belt will need to be reversed to resemble a figure 8 to rotate the engine in the right direction.

To fabricate a remote starter cart, use a 6 volt starter motor that's made for a 2N, 8N or 9N Ford farm tractor. A 12 volt starter won't have enough strength to crank over an average pulling engine. Then attach a 2" diameter steel or cast iron V-groove belt pulley on the shaft of the starter. Position a heavy duty 12 volt automotive battery at the base of the cart, a starter solenoid to activate the starter and a heavy-duty push-button type switch to activate the solenoid. And always fully charge the battery before every pull! 6 volt Ford starter motors are available on eBay if one is needed for a starter cart.

A high-torque Chevrolet V8 starter motor also works great for use on an auxiliary starter cart. A small diameter V-groove pulley in the starter mounting housing will need to installed in place of the starter drive and the V-belt will need to be installed on the pulley inside the housing.

Steer Your Tractor Straight Down the Track Using Your Body Weight!

Sometimes there is no "best way" to make both rear tires to pull equally or straight down the track. If your tractor start to head toward the boundary line, use your body weight to try to steer the tractor straight. Don't slide your butt from side to side in the seat. Doing that could cause the tractor to jerk and lose traction. Just lean your chest or upper part of your body from side to side. Lean to one side or the other. Lean the same direction the tractor is going and not the opposite way! If the tractor is headed to the right, lean to the right. In other words, lean your body toward the outside of the track. Lean a lot if you must! And it would help to lean forward too, because the front of the tractor is obviously too light. By leaning your body to either side, this places less weight on the [rear] tire that has the most traction. Also, try to place "enough" physical weight on the front of the tractor so the front tires can more or less steer the tractor straight down the track. Having a narrow rear wheel base (when the rear tires set close to the tractor frame) will help in guiding the tractor straight down the track, too.

If the front of the tractor seems too light all the time, you could...

Obviously, remove weight(s) from the rear

of the tractor and place it/them on the front.

Obviously, remove weight(s) from the rear

of the tractor and place it/them on the front.

If you don't already have one installed, and

if rules allow this, use an extendable or telescopic front weight bar. An

extended front weight bar helps to balance the tractor better so the rear

tires can dig in more. Make it the maximum length to whatever your clubs'

rules allow. Because the further out the weight extends from the rear tires,

the better the balancing effect it will have. And being most garden tractors

have somewhat of a short wheelbase, the front weight bar extension will give

a tractor the proper "balancing effect" or "front end weight flotation" that

is so critical when attempting to control the direction of the tractor on

the track. Scroll down or Click

or tap here for more information on various designs of the extendable

front weight bar.

If you don't already have one installed, and

if rules allow this, use an extendable or telescopic front weight bar. An

extended front weight bar helps to balance the tractor better so the rear

tires can dig in more. Make it the maximum length to whatever your clubs'

rules allow. Because the further out the weight extends from the rear tires,

the better the balancing effect it will have. And being most garden tractors

have somewhat of a short wheelbase, the front weight bar extension will give

a tractor the proper "balancing effect" or "front end weight flotation" that

is so critical when attempting to control the direction of the tractor on

the track. Scroll down or Click

or tap here for more information on various designs of the extendable

front weight bar.

Fabricate and install a solid steel front

axle that pivots in the center. A solid steel axle weighs about 14 lb.

It's heavier and much more durable than the [fragile] OEM cast iron piece.

Fabricate and install a solid steel front

axle that pivots in the center. A solid steel axle weighs about 14 lb.

It's heavier and much more durable than the [fragile] OEM cast iron piece.

Reposition the front axle to the extreme front

of the frame of the tractor. This makes the tractor look better, and it

gives it that "stretched" look. If the axle is moved forward, don't forget

to reinforce the frame where the engine

mounting bolt holes are or the bolt holes will break out due to normal engine

vibration and pulling stress. To move the front axle forward on a narrow

frame Cub Cadet garden tractor, first remove the engine. Then on the frame

on the narrow frame tractors, weld a brace across the frame or install an

old oil pan to keep the frame from spreading when the brace is removed.

Otherwise, the engine mounting bolt holes will not be aligned. Then raise

the front of the tractor with an overhead hoist, and use a cutting torch

and disc grinder to remove the axle support from the frame, and then locate

it forward and weld it securely in place.

Reposition the front axle to the extreme front

of the frame of the tractor. This makes the tractor look better, and it

gives it that "stretched" look. If the axle is moved forward, don't forget

to reinforce the frame where the engine

mounting bolt holes are or the bolt holes will break out due to normal engine

vibration and pulling stress. To move the front axle forward on a narrow

frame Cub Cadet garden tractor, first remove the engine. Then on the frame

on the narrow frame tractors, weld a brace across the frame or install an

old oil pan to keep the frame from spreading when the brace is removed.

Otherwise, the engine mounting bolt holes will not be aligned. Then raise

the front of the tractor with an overhead hoist, and use a cutting torch

and disc grinder to remove the axle support from the frame, and then locate

it forward and weld it securely in place.

Reposition the transaxle assembly

to the extreme rear of the frame, by drilling four new holes in the frame.

This will lengthen the tractor's appearance and wheelbase. The transaxle

can be moved rearward as far as 6", using only 4 bolts to fasten it to the

frame. And instead of making a new, longer

driveshaft, you can use the present one by fabricating

a longer coupler made of .626" i.d. x 9" long heavy wall steel tubing. Run

the tubing about 1" up on the driveshaft for better stability. Exception:

The tubular coupler used on models 800, 1000, 1200 and 582 can be made just

6" longer, because these couplers already have a lot of contact with the

driveshaft, if original driveshaft dimensions are used. The brake linkage

and maybe the shift lever will also need to be lengthened 6". And unless

the driver/operator is a very tall person with long legs (to reach the pedals),

leave the seat and fenders in their original position.

Reposition the transaxle assembly

to the extreme rear of the frame, by drilling four new holes in the frame.

This will lengthen the tractor's appearance and wheelbase. The transaxle

can be moved rearward as far as 6", using only 4 bolts to fasten it to the

frame. And instead of making a new, longer

driveshaft, you can use the present one by fabricating

a longer coupler made of .626" i.d. x 9" long heavy wall steel tubing. Run

the tubing about 1" up on the driveshaft for better stability. Exception:

The tubular coupler used on models 800, 1000, 1200 and 582 can be made just

6" longer, because these couplers already have a lot of contact with the

driveshaft, if original driveshaft dimensions are used. The brake linkage

and maybe the shift lever will also need to be lengthened 6". And unless

the driver/operator is a very tall person with long legs (to reach the pedals),

leave the seat and fenders in their original position.

Advertisement:

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. |

Bolts for Driveshaft Couplers

below Ê. Makes for easier installation

and removal of driveshaft assembly, or disconnection of coupler when changing

top input pinion gear/shaft. Bolt: 1/4" diameter x 1-3/4" length, partial

thread. Includes nylon-inserted lock nut. Bolts for Driveshaft Couplers

below Ê. Makes for easier installation

and removal of driveshaft assembly, or disconnection of coupler when changing

top input pinion gear/shaft. Bolt: 1/4" diameter x 1-3/4" length, partial

thread. Includes nylon-inserted lock nut.

|

OEM stock-length (replaces

Cub Cadet part # IH-394036-R1) or 3" aftermarket rigid tubular carbon steel

driveshaft one-piece rigid tubular couplers for Cub Cadet garden tractor

models 70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126 and 128.

And one-piece couplers to replace rubber flex coupler(s) and T-arms on "Quiet

Line" Cub Cadet garden tractor models 800, 1000, 1050 and 1200 when using

solid motor mounts (The 800, 1000 and 1200

coupler will come with two roll pin holes for single or double rubber flex

coupler(s).) Also custom-length rigid tubular driveshaft couplers, up to

6" in length are available. For a custom-length coupler, exact locations

where the spiral/roll pin holes need to be drilled are required. To find

the location of the spiral/roll pin holes, install the driveshaft in the

tractor with the engine fastened to the frame with a couple of bolts, make

sure the clutch disc is midway on the drive pins, then measure precisely

from the rear spiral/roll pin hole on the driveshaft to the spiral/roll pin

hole in the input shaft in the transaxle, then add 3/4" for the overall length

of the coupler. NOTE: The

3" aftermarket coupler is used only for competition pulling tractors

with a shortened driveshaft so the input pinion gear/shaft can be changed

to vary the ground speed of the tractor. And when ordering,

please specify model of Cub Cadet garden tractor, overall length and spiral/roll

pin hole locations. OEM stock-length (replaces

Cub Cadet part # IH-394036-R1) or 3" aftermarket rigid tubular carbon steel

driveshaft one-piece rigid tubular couplers for Cub Cadet garden tractor

models 70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126 and 128.

And one-piece couplers to replace rubber flex coupler(s) and T-arms on "Quiet

Line" Cub Cadet garden tractor models 800, 1000, 1050 and 1200 when using

solid motor mounts (The 800, 1000 and 1200

coupler will come with two roll pin holes for single or double rubber flex

coupler(s).) Also custom-length rigid tubular driveshaft couplers, up to

6" in length are available. For a custom-length coupler, exact locations

where the spiral/roll pin holes need to be drilled are required. To find

the location of the spiral/roll pin holes, install the driveshaft in the

tractor with the engine fastened to the frame with a couple of bolts, make

sure the clutch disc is midway on the drive pins, then measure precisely

from the rear spiral/roll pin hole on the driveshaft to the spiral/roll pin

hole in the input shaft in the transaxle, then add 3/4" for the overall length

of the coupler. NOTE: The

3" aftermarket coupler is used only for competition pulling tractors

with a shortened driveshaft so the input pinion gear/shaft can be changed

to vary the ground speed of the tractor. And when ordering,

please specify model of Cub Cadet garden tractor, overall length and spiral/roll

pin hole locations.

|

Lower the hitch height

slightly or reposition the hook point closer toward the transaxle. The

best position for the hook point is 6-1/2" to 8" rearward from the centerline

of the rear axle.

Lower the hitch height

slightly or reposition the hook point closer toward the transaxle. The

best position for the hook point is 6-1/2" to 8" rearward from the centerline

of the rear axle.

Pull in a slightly faster

gear.

Pull in a slightly faster

gear.

Install a smaller diameter

steering wheel so the driver/operator

can lean forward more.

Install a smaller diameter

steering wheel so the driver/operator

can lean forward more.

Use aluminum wheels on the rear. Scroll

down or Click or tap here for more

information.

Use aluminum wheels on the rear. Scroll

down or Click or tap here for more

information.

Fabricate and install aluminum or fiberglass

rear fenders. For safety reasons, do not remove the fenders entirely!

And be aware if using fiberglass. It has been known to crack due to normal

engine/tractor vibration. When fastening it, use some fender washers to

distribute the load.

Fabricate and install aluminum or fiberglass

rear fenders. For safety reasons, do not remove the fenders entirely!

And be aware if using fiberglass. It has been known to crack due to normal

engine/tractor vibration. When fastening it, use some fender washers to

distribute the load.

Fabricate and install an aluminum seat with

a short raised back (approximately 3").

Fabricate and install an aluminum seat with

a short raised back (approximately 3").

Use less oil in the transaxle. To do this,

don't fill the transaxle full of oil (to the full level hole). Instead, tap

another fill hole 2" (on the rear cover) below the original one and fill

it up to there. The lower driven gears and the ring gear will still pick

up plenty of oil and sling it on the upper moving parts, keeping them well

lubricated. A grease fitting may need to be tapped into each axle housing

end to help keep them lubricated as well.

Use less oil in the transaxle. To do this,

don't fill the transaxle full of oil (to the full level hole). Instead, tap

another fill hole 2" (on the rear cover) below the original one and fill

it up to there. The lower driven gears and the ring gear will still pick

up plenty of oil and sling it on the upper moving parts, keeping them well

lubricated. A grease fitting may need to be tapped into each axle housing

end to help keep them lubricated as well.

Install a set of cast aluminum axle housings off of certain models of older

IH Cub Cadet garden tractors. They'll about 12 lbs. lighter than the cast

iron ones. And the aluminum axle housings are just as strong as the cast

iron ones. There's no way to break one. They can be machined for the larger

Chrysler axle bearing and oil seal, too.

Install a set of cast aluminum axle housings off of certain models of older

IH Cub Cadet garden tractors. They'll about 12 lbs. lighter than the cast

iron ones. And the aluminum axle housings are just as strong as the cast

iron ones. There's no way to break one. They can be machined for the larger

Chrysler axle bearing and oil seal, too.

To save even more on weight, use an aluminum transaxle case and an aluminum

reduction gear housing that's available on certain later models of Cub Cadet

garden tractors and aftermarket ones made by

Midwest Super Cub. By the way

- the aluminum transaxle housing and casings are definitely strong enough

for competition pulling. Just remember when installing the bolts, use bolts

with threads that's long enough to go deep into the aluminum so they won't

strip out under stress or pressure.

To save even more on weight, use an aluminum transaxle case and an aluminum

reduction gear housing that's available on certain later models of Cub Cadet

garden tractors and aftermarket ones made by

Midwest Super Cub. By the way

- the aluminum transaxle housing and casings are definitely strong enough

for competition pulling. Just remember when installing the bolts, use bolts

with threads that's long enough to go deep into the aluminum so they won't

strip out under stress or pressure.

The IH Cub Cadet garden tractor cast iron complete transaxle without any internal parts weighs about 97 lbs. And the aftermarket aluminum reduction housing, transaxle case and Cub Cadet garden tractor aluminum axle housings all together weighs about 49 lbs.

Set the rear tires (wheels) inward or closer

to the frame so the driver/operator can lean with less body weight and guide

the tractor better. To do this with steel wheels, the centers will need

to be moved in the wheels. There's also aluminum wheels available with various

offsets for doing this. The fact that a lot of pullers like to use aluminum

wheels instead of steel ones isn't necessarily because

they look nice, it's because they're much lighter in weight then steel. They

create less rotating mass that robs the engine of power, and they help the

weight-conscience puller. Two steel 5-hole garden tractor wheels (Cub Cadet,

John Deere, Sears Suburban, Wheel Horse, etc.) that's been widened to 13"

weighs about 42 lb. And two 12" wide rear (Douglas) aluminum wheels weigh

in at a mere 12 lb.

Set the rear tires (wheels) inward or closer

to the frame so the driver/operator can lean with less body weight and guide

the tractor better. To do this with steel wheels, the centers will need

to be moved in the wheels. There's also aluminum wheels available with various

offsets for doing this. The fact that a lot of pullers like to use aluminum

wheels instead of steel ones isn't necessarily because

they look nice, it's because they're much lighter in weight then steel. They

create less rotating mass that robs the engine of power, and they help the

weight-conscience puller. Two steel 5-hole garden tractor wheels (Cub Cadet,

John Deere, Sears Suburban, Wheel Horse, etc.) that's been widened to 13"

weighs about 42 lb. And two 12" wide rear (Douglas) aluminum wheels weigh

in at a mere 12 lb.

Doing any of the three options listed below

Ê will add "leverage" to the front end.

In other words, it'll place more pressure on the drawbar and rear tires (making

them dig in more), and making it somewhat difficult for the front end to

rise when pulling. Otherwise, with the frame somewhat parallel with the ground,

the tractor is [kind of like] already doing a wheelie, even when it's not

in motion. So with the frame level and when it actually does a wheelie (while

pulling the sled), very little weight will be transferred upon the rear tires.

Doing any of the three options listed below

Ê will add "leverage" to the front end.

In other words, it'll place more pressure on the drawbar and rear tires (making

them dig in more), and making it somewhat difficult for the front end to

rise when pulling. Otherwise, with the frame somewhat parallel with the ground,

the tractor is [kind of like] already doing a wheelie, even when it's not

in motion. So with the frame level and when it actually does a wheelie (while

pulling the sled), very little weight will be transferred upon the rear tires.

Advertisement:

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. |

A-1 Miller's Modification

Service - Install weld-in spindle shafts in YOUR steering knuckles to

lower front of tractor 2-3/8"±

for wide or spread frame Cub Cadet garden tractor model 86, 108, 109, 128,

129, 149, 169, 582, 582 Special, 680, 682, 782, 800, 882, 1000, 1050, 1100,

1200, 1204, 1210, 1211, 1250, 1282, 1450, 1512, 1535 and 1650. An innovative

concept by Brian Miller, because nobody else advertise this type of

service. A-1 Miller's Modification

Service - Install weld-in spindle shafts in YOUR steering knuckles to

lower front of tractor 2-3/8"±

for wide or spread frame Cub Cadet garden tractor model 86, 108, 109, 128,

129, 149, 169, 582, 582 Special, 680, 682, 782, 800, 882, 1000, 1050, 1100,

1200, 1204, 1210, 1211, 1250, 1282, 1450, 1512, 1535 and 1650. An innovative

concept by Brian Miller, because nobody else advertise this type of

service.

|

| Front Tires, Front Wheels, Inner Tubes and Wheelie Bar Wheels - |

4.10/3.50-4 Heavy Duty,

Flat-Free, Tire and Wheel Assembly. 4.10/3.50-4 Heavy Duty,

Flat-Free, Tire and Wheel Assembly.

Features: Puncture resistant! Shock-absorbing! Zero down time! Never needs inflating! Less weight than standard 3-piece pneumatic tire and wheel assemblies. Excellent resistance to abrasion, water absorption, and chemical attacks. Maintains low rolling resistance. Double-sealed, semi-precision 3/4" ball bearings that offer higher wear resistance, quiet and smooth operation. Pre-greased to extend bearing life. Specifications: 10.2" diameter x 3.2" wide. Tire weight load capacity: 350 lbs.

|

4.10x3.50-4 Sawtooth Tread

2-Ply Tubeless Tire. Fully inflated dimensions: 4.1" width of sidewall bulge

x 11" overall height x 4" rim diameter. Each tire weighs 2.8 lbs. Load capacity

for each tire is 260 lbs @ 30 psi. (maximum inflation). Made by Carlisle.

Proportional size to the 23-10.50x12 rear tires. 4.10x3.50-4 Sawtooth Tread

2-Ply Tubeless Tire. Fully inflated dimensions: 4.1" width of sidewall bulge

x 11" overall height x 4" rim diameter. Each tire weighs 2.8 lbs. Load capacity

for each tire is 260 lbs @ 30 psi. (maximum inflation). Made by Carlisle.

Proportional size to the 23-10.50x12 rear tires.

4.10-6 Sawtooth Tread 4-Ply Tubeless Tire. Fully inflated dimensions: 4.1" width of sidewall bulge x 13" overall height x 6" rim diameter. Each tire weighs 3.1 lbs. Load capacity for each tire is 485 lbs. @ 85 psi. (maximum inflation). Made by Carlisle. Proportional size to the 26-12.00x12 rear tires.

|

11x400-5 Rib Tread 2-Ply

Tubeless Tire. Fully inflated dimensions: 11" overall height x 4" width of

sidewall bulge x 5" rim diameter. Each tire weighs 3.5 lbs. Load capacity

for each tire is 210 lbs. @ 22 psi. (maximum inflation). Made by Cheng Shin.

"In-between" proportional size to the 23-10.50x12 or 26-12.00x12 rear

tires. 11x400-5 Rib Tread 2-Ply

Tubeless Tire. Fully inflated dimensions: 11" overall height x 4" width of

sidewall bulge x 5" rim diameter. Each tire weighs 3.5 lbs. Load capacity

for each tire is 210 lbs. @ 22 psi. (maximum inflation). Made by Cheng Shin.

"In-between" proportional size to the 23-10.50x12 or 26-12.00x12 rear

tires.

13x500-6 Rib Tread 2-Ply Tubeless Tire. Fully inflated dimensions: 11" overall height x 4" width of sidewall bulge x 6" rim diameter. Each tire weighs 4.5 lbs. Load capacity for each tire is 295 lbs. @ 20 psi. (maximum inflation). Made by Cheng Shin. Proportional size to the 26-12.00x12 rear tires.

|

Two-Piece,

Bolt-Together Steel Wheels for Easier Mounting and Dismounting, 4" wheel.

Painted white. Dimensions: 4" diameter x 2-1/2" rim width x 2-1/8" wide centered

hub. (Cub Cadet garden tractor front spindles are 3" long, so a 3/4" spacer

will need to be used with this wheel.) Two wheels weighs 4.2 lbs. Accepts

1-3/8" o.d. bearings or bushings (not included); use with inner tube. Two-Piece,

Bolt-Together Steel Wheels for Easier Mounting and Dismounting, 4" wheel.

Painted white. Dimensions: 4" diameter x 2-1/2" rim width x 2-1/8" wide centered

hub. (Cub Cadet garden tractor front spindles are 3" long, so a 3/4" spacer

will need to be used with this wheel.) Two wheels weighs 4.2 lbs. Accepts

1-3/8" o.d. bearings or bushings (not included); use with inner tube.

Two-Piece, Bolt-Together Steel Wheels for Easier Mounting and Dismounting. 6" wheel. Painted white. Dimensions: 5" diameter x 2-3/4" rim width x 3-1/2" wide centered hub. (Cub Cadet garden tractor front spindles are 3" long, so a 3/4" spacer will need to be used with this wheel.) Two wheels weighs 5.2 lbs. Accepts 1-3/8" o.d. bearings or bushings (not included); use with inner tube.

Two-Piece, Bolt-Together Steel Wheels for Easier Mounting and Dismounting. 6" wheel. Painted white. Dimensions: 6" diameter x 3-1/4" rim width x 3-1/2" wide centered hub. (Cub Cadet garden tractor front spindles are 3" long, so a 3/4" spacer will need to be used with this wheel.) Two wheels weighs 6.2 lbs. Accepts 1-3/8" o.d. bearings or bushings (not included); use with inner tube.

|

Inner Tubes -

Each have a straight valve stem; Made by Cheng Shin. Inner Tubes -

Each have a straight valve stem; Made by Cheng Shin.

|

Durable Plastic Wheelie Bar Wheels with spherical (rounded)

tread surface. Dimensions: 5" tall x 2" wide x 5/8" center hole. Our part

# 07-11819. Durable Plastic Wheelie Bar Wheels with spherical (rounded)

tread surface. Dimensions: 5" tall x 2" wide x 5/8" center hole. Our part

# 07-11819.

|

Now if the front end seems too heavy or if the front tires won't "float" down the track or barely make contact with the track when pulling, what could be done to lighten the front end is...

Obviously, remove weight(s) from the front

of the tractor and place it/them on the rear.

Obviously, remove weight(s) from the front

of the tractor and place it/them on the rear.

Sharpen the tire tread if rules allow, use

a different type of tire with better tread (softer or harder rubber compound;

according to track conditions) or adjust the tire pressure accordingly.

Sharpen the tire tread if rules allow, use

a different type of tire with better tread (softer or harder rubber compound;

according to track conditions) or adjust the tire pressure accordingly.

Remove all unnecessary (mower deck) brackets,

hangers, pulleys, etc. from the front or midway of the tractor.

Remove all unnecessary (mower deck) brackets,

hangers, pulleys, etc. from the front or midway of the tractor.

Don't install the battery or fuel tank on

the extreme front end of the tractor. Or perhaps use a smaller fuel tank,

if you prefer it to be mounted on the front.

Don't install the battery or fuel tank on

the extreme front end of the tractor. Or perhaps use a smaller fuel tank,

if you prefer it to be mounted on the front.

Reposition the drawbar

further back or away from the transaxle. The best position for the drawbar

is 6-1/2" to 8" rearward from the center of the rear axle.

Reposition the drawbar

further back or away from the transaxle. The best position for the drawbar

is 6-1/2" to 8" rearward from the center of the rear axle.

If your tractor has cast aluminum axle housings, install a set of cast iron

axle housings off the early models of Cub Cadet garden tractors. The cast

iron ones that will interchange with the aluminum housings that come on all

IH models of Cub Cadet garden tractors. There's about a 12 lb. difference

between the aluminum housings and the cast iron ones. To add even more weight

on the rear, use a cast iron transaxle case and a cast iron reduction gear

housing that also come on all IH models of Cub Cadet garden tractors. By

the way - the IH Cub Cadet garden tractor cast iron complete transaxle without

any internal parts weighs about 97 lbs. And the aftermarket aluminum reduction

housing, transaxle case and Cub Cadet garden tractor aluminum axle housings

all together weighs about 49 lbs.

If your tractor has cast aluminum axle housings, install a set of cast iron

axle housings off the early models of Cub Cadet garden tractors. The cast

iron ones that will interchange with the aluminum housings that come on all

IH models of Cub Cadet garden tractors. There's about a 12 lb. difference

between the aluminum housings and the cast iron ones. To add even more weight

on the rear, use a cast iron transaxle case and a cast iron reduction gear

housing that also come on all IH models of Cub Cadet garden tractors. By

the way - the IH Cub Cadet garden tractor cast iron complete transaxle without

any internal parts weighs about 97 lbs. And the aftermarket aluminum reduction

housing, transaxle case and Cub Cadet garden tractor aluminum axle housings

all together weighs about 49 lbs.

Remove the starter/generator (if equipped)

and install the smaller gear starter with a large diameter ring gear type

flywheel. There's a 22 lb. difference between the starter/generator. bracket

and PTO pulley versus the small gear starter.

Remove the starter/generator (if equipped)

and install the smaller gear starter with a large diameter ring gear type

flywheel. There's a 22 lb. difference between the starter/generator. bracket

and PTO pulley versus the small gear starter.

Remove all starting mechanisms and use a remote

starter cart. Click or tap here for

more information on this subject.

Remove all starting mechanisms and use a remote

starter cart. Click or tap here for

more information on this subject.

Install a seat with a short(er) back support

so the driver/operator can lean back more.

Install a seat with a short(er) back support

so the driver/operator can lean back more.

Use small diameter aluminum wheels with small,

lightweight tires on the front.

Use small diameter aluminum wheels with small,

lightweight tires on the front.

If it's a slow moving stock tractor with low

tire speed, use steel wheels on the rear.

If it's a slow moving stock tractor with low

tire speed, use steel wheels on the rear.

Fabricate and install a thin-wall [reinforced]

aluminum or steel tubular front axle that pivots in the center.

Fabricate and install a thin-wall [reinforced]

aluminum or steel tubular front axle that pivots in the center.

Fabricate and install a [reinforced] aluminum,

thin-wall steel or fiberglass hood/grille support. Be aware if using

fiberglass! It has been known to crack due to normal engine vibration. When

fastening it, install a wide flat washer with a large diameter rubber washer

on each mounting bolt against the fiberglass to cushion and distribute the

load.

Fabricate and install a [reinforced] aluminum,

thin-wall steel or fiberglass hood/grille support. Be aware if using

fiberglass! It has been known to crack due to normal engine vibration. When

fastening it, install a wide flat washer with a large diameter rubber washer

on each mounting bolt against the fiberglass to cushion and distribute the

load.

If it's a high-tire-speed pulling tractor, avoid using

wheel weights or fluid in the rear tires for competition

pulling! But if you prefer to use wheel weights, the most easiest and inexpensive

way is to use barbell weights. They can be mounted by drilling a 27/64" hole

in the center of each axle (it should be soft metal), then cut some 1/2-13

threads in the drilled holes. Then install a hardened 1/2" diameter

If it's a high-tire-speed pulling tractor, avoid using

wheel weights or fluid in the rear tires for competition

pulling! But if you prefer to use wheel weights, the most easiest and inexpensive

way is to use barbell weights. They can be mounted by drilling a 27/64" hole

in the center of each axle (it should be soft metal), then cut some 1/2-13

threads in the drilled holes. Then install a hardened 1/2" diameter

threaded steel rod

(All Thread) into the threaded holes, cut the rods off so

they won't protrude too far out past the tire, slide the weights onto the

rod, and then fasten them in place with a large flat washer and wing nut.

Never run wheel weights or fluid in the rear tires

except in or on a slow moving stock tractor! In a high speed pulling tractor,

the extra rotating weight will slow the tractor down A LOT! It's based on

one of the laws of physics and mechanics: it takes more force (as in torque

and horsepower) to set a heavy object in motion than it would to spin a

lightweight object. Therefore, in pulling, the wheel weights will cause the

rear tires to lose a lot of momentum (speed) and they'll rob the engine of

valuable power. Actually, the engine would be straining because of the extra

weight.

threaded steel rod

(All Thread) into the threaded holes, cut the rods off so

they won't protrude too far out past the tire, slide the weights onto the

rod, and then fasten them in place with a large flat washer and wing nut.

Never run wheel weights or fluid in the rear tires

except in or on a slow moving stock tractor! In a high speed pulling tractor,

the extra rotating weight will slow the tractor down A LOT! It's based on

one of the laws of physics and mechanics: it takes more force (as in torque

and horsepower) to set a heavy object in motion than it would to spin a

lightweight object. Therefore, in pulling, the wheel weights will cause the

rear tires to lose a lot of momentum (speed) and they'll rob the engine of

valuable power. Actually, the engine would be straining because of the extra

weight.

Fabricate a heavy duty box, and place weight

between the rear tires, under the transaxle. This lowers the center of gravity

for the overall rear weight of the tractor and lessens the chance having

a "teeter-totter" effect, or raring up and down of the front end. And instead

of using hang-on weights that's out in the open where the competition can

see the number of weights on the tractor, it'll be better to use a sturdy

weight box with a lid on the front weight extension and at the rear of the

tractor to hide the number of weights inside.

Fabricate a heavy duty box, and place weight

between the rear tires, under the transaxle. This lowers the center of gravity

for the overall rear weight of the tractor and lessens the chance having

a "teeter-totter" effect, or raring up and down of the front end. And instead

of using hang-on weights that's out in the open where the competition can

see the number of weights on the tractor, it'll be better to use a sturdy

weight box with a lid on the front weight extension and at the rear of the

tractor to hide the number of weights inside.

To

fabricate weights yourself, find a friend with a cutting torch, cut-off saw

or chop saw and welder then check with scrap metal recycling centers. That's

what I did, and saved a bundle! Of course, I have our own acetylene cutting

torch, 14" chop saw and two wire welders.

To

fabricate weights yourself, find a friend with a cutting torch, cut-off saw

or chop saw and welder then check with scrap metal recycling centers. That's

what I did, and saved a bundle! Of course, I have our own acetylene cutting

torch, 14" chop saw and two wire welders.

When placing weight on a pulling tractor, include some smaller pieces of weights, (1 lb., 2 lb.) instead of just large, massive weights or use thick and thin weights. While on the scales, smaller pieces of weights makes it much easier to remove, add or juggle down to a pound or two. And always mark your weights so you'll know how much each one weighs. This way, it takes the guess work out of adding or removing weight as needed. And it'll be a good idea to put your name on your weights, so another puller can't claim them as theirs.

Sometimes automotive tire dealerships or tire repair shops

will give away 5 gallon buckets of used lead wheel balancing weights. Or

they'll sell a bucket full of lead weights for very little. Believe me, you

can hardly lift a full bucket of these weights! Lead wheel weights can be

easily melted down over low heat in a Teflon-coated cooking pan, a stainless

steel pan or skillet that's been coated with a non-stick cooking spray, such

as PAM® Cooking Spray

or Baker's Joy, and

then the lead can be poured into a steel or aluminum container (such as an

ice cube tray) to make certain shapes of small weights. But do this in a

well-ventilated area (outdoors) because molten lead produces caustic and

deadly gases! And don't worry about the steel clip on the weights. They won't

melt, they'll just mix in with the lead and add a little extra weight. For

more information and how-to videos on this subject, click here:

How To Melt Lead For Weights - YouTube.

Sometimes automotive tire dealerships or tire repair shops

will give away 5 gallon buckets of used lead wheel balancing weights. Or

they'll sell a bucket full of lead weights for very little. Believe me, you

can hardly lift a full bucket of these weights! Lead wheel weights can be

easily melted down over low heat in a Teflon-coated cooking pan, a stainless

steel pan or skillet that's been coated with a non-stick cooking spray, such

as PAM® Cooking Spray

or Baker's Joy, and

then the lead can be poured into a steel or aluminum container (such as an

ice cube tray) to make certain shapes of small weights. But do this in a

well-ventilated area (outdoors) because molten lead produces caustic and

deadly gases! And don't worry about the steel clip on the weights. They won't

melt, they'll just mix in with the lead and add a little extra weight. For

more information and how-to videos on this subject, click here:

How To Melt Lead For Weights - YouTube.

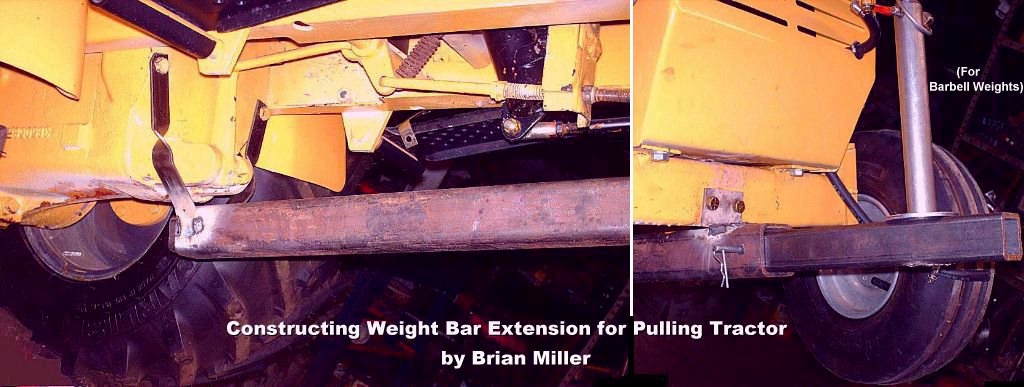

Fabricating the Front Extendable Weight Bar (Boom Extension) -

If using the "stack or "hang

on" type of weights on the front weight bar, for stack weights, a rubber

strap could be used to secure the weights in place. Or better yet, and to

make it look fancy, run a 3/8" diameter steel rod over the top of all the

weights to secure them in place. This rod can be used for the hang on type

of weights, too. Then use a hair pin clip on each end of the rod to secure

it place.

If using the "stack or "hang

on" type of weights on the front weight bar, for stack weights, a rubber

strap could be used to secure the weights in place. Or better yet, and to

make it look fancy, run a 3/8" diameter steel rod over the top of all the

weights to secure them in place. This rod can be used for the hang on type

of weights, too. Then use a hair pin clip on each end of the rod to secure

it place.

Being there are many different ways to fabricate the front weight bar extension, the below Ê is how I like to do it. (This is much easier to do on a platform work table.)

FYI - The average 1,050 lb. competition garden pulling tractor needs approximately 60-65 lbs. of weight on the front weight bar. This includes the tubing to construct the weight bar extension, weight box and/or bracket. Return È

A

Spring-Loaded Pull Pin can be used to retain the front

weight bar extension in place on a pulling tractor. A spring-loaded pull

pin allows quick and easy retraction and engagement of the locking pin or

plunger to slide the front weight extension in and out with less effort.

Easily installed. Align holes and weld base to the outer weight bar extension

housing. Pulling on the handle of the plunger assembly retracts the plunger

into the housing. Releasing the handle allows the spring-loaded plunger to

extend. The lockout design allows the handle to be pulled and rotated 1/4

turn to hold the plunger in the retracted position.

A

Spring-Loaded Pull Pin can be used to retain the front

weight bar extension in place on a pulling tractor. A spring-loaded pull

pin allows quick and easy retraction and engagement of the locking pin or

plunger to slide the front weight extension in and out with less effort.

Easily installed. Align holes and weld base to the outer weight bar extension

housing. Pulling on the handle of the plunger assembly retracts the plunger

into the housing. Releasing the handle allows the spring-loaded plunger to

extend. The lockout design allows the handle to be pulled and rotated 1/4

turn to hold the plunger in the retracted position.

To make a place to add weights on the rear of your tractor, fabricate an 1/8" flat steel plate above the drawbar to place some "hang on" weights onto. And use a rubber strap or fasten a steel rod over the top of the weights to secure them in place. Or fabricate a long, narrow metal box with a locking lid to place odd shapes of weight into.

To add even more weight and to "balance" the tractor out a little better, a bracket could be fabricated under the frame/in front of each rear tire to hang some weight onto. Or better yet, when at a pull, walk around and look over the competitive (winning) pulling tractors, to get some idea on how and where they place their weights.

And if only if the same person pulls the same tractor all the time, or if one don't need to remove weight(s) from a tractor often, you could "disguise" the weight(s) or hide it/them by fabricating a heavier, thicker steel grille/hood support or front axle, fabricate some heavier, thicker steel fenders, fasten weight inside the frame rails, etc. Also, avoid using inside mounted rear wheel weights.

Weight of Various Materials

-

If you don't have a scale to weigh your steel or lead, here's the formulas to figure the weight of these metals: (All measurements shown are in inches. And it's best to use a calculator for these.)

When placing ballast weight in the weight box(es) of a pulling tractor, try to avoid using material that's very porous or has a lot of "empty space" inside it. The empty space takes up a lot of valuable room that could be filled with other metal. Therefore, it's best to use solid blocks or plates of steel, cast iron or better yet, lead.

Click

Here for Detailed Illustrated Plans on How to Construct a Professional Pull-Back

and Self-Propelled Garden Tractor Pulling Sled (Available

Soon)

FYI - The self-propelled garden tractor pulling sled that I built is such

an excellent design, I realized later that I made something very special

when other people copied after it. - Brian Miller

Click

Here for Detailed Illustrated Plans on How to Construct a Professional Pull-Back

and Self-Propelled Garden Tractor Pulling Sled (Available

Soon)

FYI - The self-propelled garden tractor pulling sled that I built is such

an excellent design, I realized later that I made something very special

when other people copied after it. - Brian Miller

To

place an order, send your item(s) for repairing, and/or for customer service

assistance, and FREE honest and accurate technical support, please contact:

A-1 Miller's Performance Enterprises, 12091 N Route B, Hallsville, MO (Missouri)

65255-9604 USA. Please call in your order or send an email with a list parts

you need and your contact information.

To

place an order, send your item(s) for repairing, and/or for customer service

assistance, and FREE honest and accurate technical support, please contact:

A-1 Miller's Performance Enterprises, 12091 N Route B, Hallsville, MO (Missouri)

65255-9604 USA. Please call in your order or send an email with a list parts

you need and your contact information.

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

Whatsapp. Please call

Monday-Friday, 9am to 5pm, Central time zone, except holidays. If no answer,

please try again later. (When speaking with Brian on the phone, please

be patient and understanding because I stutter.)

Phone: 1-573-881-7229 (cell;

call, text or leave voicemail) or use

Whatsapp. Please call

Monday-Friday, 9am to 5pm, Central time zone, except holidays. If no answer,

please try again later. (When speaking with Brian on the phone, please

be patient and understanding because I stutter.)

E-mail:

pullingtractor@aol.com.

Payment Options. A-1 Miller's shop is open

to the public Monday-Friday, 9am to 5pm, Central time zone, with an appointment

on weekends, except holidays. If you're the kind of person who don't trust

delivery/shipping companies (mis)handling your high-dollar and fragile

merchandise, you can make the long drive to

A-1 Miller's new shop (click image

to the right) to personally purchase parts, or drop off and/or pick up your

carburetor, clutch assembly, engine and/or parts, etc., for repairing and/or

rebuilding. Or visit the address of our (old) shop mentioned above to drop

off your engine, transmission, transaxle, garden tractor, small motorized

vehicle, etc. We also custom build pulling tractors and other small vehicles.

Please contact me before coming so I'll be at my shop waiting for your arrival.

When you visit our shop, you will be dealing directly with the owner for

the best customer service.

12091 N Route B, Hallsville, MO - Google Maps "The road

to a [trusted] friend's house (or shop) is never long." Don't sacrifice quality

workmanship for distance. [Return

To Previous Paragraph, Section or Website]

E-mail:

pullingtractor@aol.com.

Payment Options. A-1 Miller's shop is open

to the public Monday-Friday, 9am to 5pm, Central time zone, with an appointment

on weekends, except holidays. If you're the kind of person who don't trust

delivery/shipping companies (mis)handling your high-dollar and fragile

merchandise, you can make the long drive to

A-1 Miller's new shop (click image

to the right) to personally purchase parts, or drop off and/or pick up your

carburetor, clutch assembly, engine and/or parts, etc., for repairing and/or

rebuilding. Or visit the address of our (old) shop mentioned above to drop

off your engine, transmission, transaxle, garden tractor, small motorized

vehicle, etc. We also custom build pulling tractors and other small vehicles.

Please contact me before coming so I'll be at my shop waiting for your arrival.

When you visit our shop, you will be dealing directly with the owner for

the best customer service.

12091 N Route B, Hallsville, MO - Google Maps "The road

to a [trusted] friend's house (or shop) is never long." Don't sacrifice quality

workmanship for distance. [Return

To Previous Paragraph, Section or Website]

By the way - As business is booming, we relocated our business at 12091 N. Route B, Hallsville, MO 65255 with a new, bigger, better, fully insulated, heated and air-conditioned building/shop (shouse) so we can provide many more professional services and high quality parts, and hire more reliable and knowledgeable help to have our customer's parts orders fulfilled sooner, parts repaired sooner and engine rebuilds performed promptly without a long delay. We will also offer custom welding fabrication jobs and other custom services. And we also provide pick up and delivery service and perform professional repairs for various small engines and lawn & garden equipment! Photos of our new building/shop are posted here! 12091 N Rte B, Hallsville, MO - Google Maps

Payment Options, and We Ship to Canada and

Worldwide

Item(s) in a package or cushioned envelope weighing less than 1 lb. is sent

by US Postal Service Airmail Letter Post for a 4-7 days delivery. Packaged

item(s) weighing over 1 lb. and up to 66 lb. is sent by US Postal Service

Airmail Parcel Post for a 4-10 days delivery. I cannot use the US Postal

Services' Flat Rate Priority Mail envelopes and boxes to ship outside U.S.

territories. Item(s) weighing over 67 lbs. or more is sent by FedEx Ground

or equivalent services. We try to keep our shipping cost to customers within

reason. Therefore, we don't ship our products in a fancy-looking package

with our company name and/or logo on it because most customers will just

toss it in the trash after they remove the contents. And being there is no

USPS tracking number outside the US, all I can do is make sure I write your

address correctly on the customs form and on your package.

My websites are not set up to process orders and accept payments. Therefore, to place an order with me, please call either number above or send an email with a list of parts you need, with your name, complete and correct postal mailing address and phone number. For payment options, I accept cash (in person), USPS Postal Money Orders, cashier's checks, business checks, MasterCard, VISA, Discover, American Express (please add 2.5% to the total amount for the credit/debit card processor's surcharge). If paying with a credit/debit card, please call me at either number above. Or to make a payment to me through PayPal, please click this link: https://www.paypal.com. Or use Cash App (username: pullingtractor) or Venmo (username: Pullingtractor) to make a payment to me. And be sure to mention a description of what the payment is for with your full name, postal address, phone number and email address. I also accept payments through Western Union Money Transfer or MoneyGram Money Transfers. If sending a money order or cashier's check, please include a note in the envelope with your name, complete mailing address, phone number, email address and a description of what the payment is for. I'll make a note of your order when I have all your information, and I may have to order some of the parts on your list, which should take a few days to come in, but I will send everything to you as soon as I have the parts in stock after I receive your payment.

à Return to Main Pulling Tips Page | Return To Previous Website | Various Vendors Related to Tractor Pulling | Top of Page

Copyright © 1996-Present. This website created, designed and maintained by Brian Miller.