Information about the Cub Cadet Garden Tractor Creeper Drive

and How to Improve and Modify the Cub Cadet Transaxle for Heavy Duty Use

and/or for Competition Pulling

Information about the Cub Cadet Garden Tractor Creeper Drive

and How to Improve and Modify the Cub Cadet Transaxle for Heavy Duty Use

and/or for Competition Pulling

Information about the Cub Cadet Garden Tractor Creeper Drive

and How to Improve and Modify the Cub Cadet Transaxle for Heavy Duty Use

and/or for Competition Pulling

Information about the Cub Cadet Garden Tractor Creeper Drive

and How to Improve and Modify the Cub Cadet Transaxle for Heavy Duty Use

and/or for Competition Pulling

Inspiring Small Engine, Lawn & Garden, and Garden Pulling Tractor Enthusiasts Since 1996. Where Science and Common Sense Come Together for Safety and Improved Engine/Tractor Performance | A-1 Miller's Performance Enterprises - Parts & Services Online Catalog

Nowadays, prices are subject to change without notice. Click

Refresh to see any

changes or updates. Optimized for 1152 x 864 computer screen resolution.

To search for a word or phrase in any of my websites, press the CTRL

and F

and F  keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. Click links below to jump down to the article or scroll down

in this website.

keys on

your keyboard simultaneously to open the Find or Search dialog box in your

web browser. Click links below to jump down to the article or scroll down

in this website.

What type of oil should be used in the Cub Cadet garden tractor and other makes and models of gearboxes, transmissions and transaxles? (Updated 3/27/16)

For the IH- and MTD-built Cub Cadet

garden tractor hydrostatic- and gear-drive transaxles, the official Cub Cadet

garden tractor repair manual says the recommended oil to use is Hy-Tran B-6,

Hy-Tran PLUS (MS-1207), Hy-Tran ULTRA or equivalent. "Equivalent" means that

it's safe to use any high quality, name-brand hydraulic oil that meets or

exceeds CASE

IH requirements. These oils can be used in both the hydrostatic (and

hydraulic) drive and gear drive transaxles. Most

Farm and Home retail stores should have Hy-Tran oil in

stock. When or if you do find Hy-Tran, look on the back label of the CASE

IH hydraulic oil containers. It should mention something about Hy-Tran. By

the way - Allegedly, IH Cub Cadet and CASE IH (and perhaps other

tractor/transaxle manufacturers) made a deal with the makers of Hy-Tran,

and this is why they highly recommend to use their oil. It's all about more

money for the big business. They figure what the public don't know makes

them more money.

For the IH- and MTD-built Cub Cadet

garden tractor hydrostatic- and gear-drive transaxles, the official Cub Cadet

garden tractor repair manual says the recommended oil to use is Hy-Tran B-6,

Hy-Tran PLUS (MS-1207), Hy-Tran ULTRA or equivalent. "Equivalent" means that

it's safe to use any high quality, name-brand hydraulic oil that meets or

exceeds CASE

IH requirements. These oils can be used in both the hydrostatic (and

hydraulic) drive and gear drive transaxles. Most

Farm and Home retail stores should have Hy-Tran oil in

stock. When or if you do find Hy-Tran, look on the back label of the CASE

IH hydraulic oil containers. It should mention something about Hy-Tran. By

the way - Allegedly, IH Cub Cadet and CASE IH (and perhaps other

tractor/transaxle manufacturers) made a deal with the makers of Hy-Tran,

and this is why they highly recommend to use their oil. It's all about more

money for the big business. They figure what the public don't know makes

them more money.

But if Hy-Tran isn't available locally,

then it's absolutely safe to use virtually any brand of

Automatic Transmission Fluid (ATF), hydraulic oil, power

steering fluid, hydraulic jack oil (which is nothing but low viscosity/thinner

hydraulic oil) in a Cub Cadet garden tractor gear drive transaxle or hydrostatic

drive. Automatic Transmission Fluid is a very durable and high quality hydraulic

oil with a red dye and scent added to determine it from other oils when it

leaks from a vehicle or equipment. It also has a rust inhibitor and has a

cleaning agent, which helps keep the inside of a transaxle clean. By the

way - automatic transmission fluid protects automotive automatic transmission

parts, don't they? And auto transmissions work a lot harder and operate for

longer periods of time (while hauling heavy loads on the highway and up steep

grades) than any garden tractor transaxle ever will. Synthetic oils will

allow the internal moving parts to operate much cooler. And to prevent the

wear of gears in hydraulic pumps and motors, ALWAYS use a hydraulic type

of oil in a hydrostatic drive and hydraulic system because it's formulated

to flow more easily and freer past the moving parts.

But if Hy-Tran isn't available locally,

then it's absolutely safe to use virtually any brand of

Automatic Transmission Fluid (ATF), hydraulic oil, power

steering fluid, hydraulic jack oil (which is nothing but low viscosity/thinner

hydraulic oil) in a Cub Cadet garden tractor gear drive transaxle or hydrostatic

drive. Automatic Transmission Fluid is a very durable and high quality hydraulic

oil with a red dye and scent added to determine it from other oils when it

leaks from a vehicle or equipment. It also has a rust inhibitor and has a

cleaning agent, which helps keep the inside of a transaxle clean. By the

way - automatic transmission fluid protects automotive automatic transmission

parts, don't they? And auto transmissions work a lot harder and operate for

longer periods of time (while hauling heavy loads on the highway and up steep

grades) than any garden tractor transaxle ever will. Synthetic oils will

allow the internal moving parts to operate much cooler. And to prevent the

wear of gears in hydraulic pumps and motors, ALWAYS use a hydraulic type

of oil in a hydrostatic drive and hydraulic system because it's formulated

to flow more easily and freer past the moving parts.

For competition pulling only in a gear drive transaxle (not the creeper drive), don't use heavy, thick 80W90 gear oil. Gear oil will rob the engine of horsepower because the gears can't rotate freely at higher speeds due to the thicker oil. Therefore, Hy-Tran, hydraulic oil, automatic transmission fluid, or SAE 30, 10W30 or 10W40 motor oil should be used instead. These low viscosity (thinner) oils will allow the gears to spin more freely and provide adequate lubrication for all moving parts. So there's no need to worry about the gears, bearings and other internal parts wearing prematurely because of the thinner oil. The parts in garden tractor transaxles are made of extremely hardened material. And being gear drive transaxles don't have a hydraulic pump like the hydrostatic drive and hydraulic systems do, which build-up heat due to extreme pressure exerted from the pump (this is why certain hydrostatic drive and hydraulic systems have an oil cooler), the oil will never get hot.

For prolong and general yard and garden use, 75W90 or 80W90 gear oil should be used in the IH and MTD Cub Cadet garden tractor creeper drives, right-angle gearboxes, and Peerless, Wheel Horse and any other gear-drive transaxle, except the Cub Cadet garden tractor transaxle with an internal brake. The thicker 80W90 gear oil will not "thin out" for a long period of heavy duty use and will provide adequate lubrication and protection for the gears, bearings and oil seals.

When filling the Cub Cadet garden tractor internal brake transaxle with oil, 75W90 or 80W90 gear oil shouldn't be used. If heavy gear oil is used, the internal brake will not grip as well and the tractor will not stop as well. Instead, use Hy-Tran fluid. But 0W20 full synthetic, SAE 30 or 10W30 motor oils, power steering fluid, SAE 10 weight hydraulic oil, automatic transmission fluid (ATF) can be used as a substitute. These type of oils are much thinner than 75W90 and 80W90 gear oils, which will allow the brake to grip better, plus, thinner oil allows the gears to spin faster, freeing up horsepower in a high-speed competition pulling tractor. And don't worry about the internal parts wearing because of the thinner oil. They're made of extremely hardened material.

Oil for the IH Cub Cadet "Original" garden tractor transaxle is installed through the oil fill hole on top of the transaxle, just behind the shift lever. And the oil level check hole is located on the lower right side of the transaxle, towards the front. Fill with oil until it runs out of the hole on the side. Oil for all other models of Cub Cadet garden tractor transaxles, including the gear drive and hydrostatic drive, is installed and added through the oil fill/level hole (with a 1/2" drive NPT tapered-thread plug) that's on the rear cover of the transaxle. An automotive automatic transmission funnel with a long, flexible tube may need to be used to put the oil in. Fill the transaxle until the oil starts to run out of the hole. On a transaxle that's just been rebuilt or modified, it's a lot easier and less effort to install the oil through the shift lever opening, before installing the shift lever housing, then check the level at the hole in the rear cover. Make sure the transaxle is positioned level too, for accuracy. And it takes 3-1/2 quarts of oil to fill an IH Cub Cadet garden tractor gear drive transaxle.

What is the Difference Between 75W90 and 80W90 Gear Oil?

75W90 gear oil provides better cold-weather flow and and longer life due to its generally synthetic, higher-quality base oil, while 80W90 gear oil is a mineral-based option with a thicker base oil and less reliance on polymers for viscosity, leading to more consistent viscosity, but less cold-weather performance. For mostly warm weather use, the 80W90 is suitable, but in warm and cold weather use, 75W90 is often a smarter, more protective option for overall efficiency, especially in creeper drives, gearboxes, transmissions, transaxles and differentials with components that benefit from a thinner, more consistent oil.

What makes most hydrostatic drive

and driven parts and gears wear prematurely isn't because the wrong type

of oil is used, it's due to extreme

HEAT. Whenever petroleum

oil gets hot, it loses it's "thickness" or viscosity and turns very thin,

or "thins out," in other words. The hotter it gets, the thinner it gets.

This is called

thermal viscosity breakdown. Oil is supposed to keep all

internal moving engine parts and rotating gears safely lubricated and most

importantly, separated. But when oil gets hot, it gets thin, and this will

cause the moving parts (gears and such) to make physical contact with each

other (metal to metal contact) causing them to wear excessively. Extremely

hot oil will cause the rubber seals to harden and crack, too. No petroleum

oil, not even Hy-Tran, is immune from thermal viscosity breakdown. Synthetic

blend oil, also known as part-synthetic or semi-synthetic oil, is a mixture

of conventional mineral oil and full synthetic oil. Synthetic blend oil is

50% immune from thermal viscosity breakdown. But only full synthetic oil

, which is a motor oil engineered at the molecular level using chemically

synthesized base oils, rather than being derived from crude oil, is 100%

immune from thermal viscosity breakdown. So remember, it's very important

to keep the oil changed regularly, keep the cooling fins that's on the

hydrostatic pump/motor clean and free of debris, make sure the fan that blows

cooling air over the hydrostatic pump/motor is in good, working condition,

and perform thorough routine maintenance at least once a year before using

the tractor or equipment, and the hydrostatic unit will probably last forever.

By the way - it takes approximately 7 quarts of oil to fill the Cub Cadet

garden tractor hydrostatic drive transaxle and filter.

What makes most hydrostatic drive

and driven parts and gears wear prematurely isn't because the wrong type

of oil is used, it's due to extreme

HEAT. Whenever petroleum

oil gets hot, it loses it's "thickness" or viscosity and turns very thin,

or "thins out," in other words. The hotter it gets, the thinner it gets.

This is called

thermal viscosity breakdown. Oil is supposed to keep all

internal moving engine parts and rotating gears safely lubricated and most

importantly, separated. But when oil gets hot, it gets thin, and this will

cause the moving parts (gears and such) to make physical contact with each

other (metal to metal contact) causing them to wear excessively. Extremely

hot oil will cause the rubber seals to harden and crack, too. No petroleum

oil, not even Hy-Tran, is immune from thermal viscosity breakdown. Synthetic

blend oil, also known as part-synthetic or semi-synthetic oil, is a mixture

of conventional mineral oil and full synthetic oil. Synthetic blend oil is

50% immune from thermal viscosity breakdown. But only full synthetic oil

, which is a motor oil engineered at the molecular level using chemically

synthesized base oils, rather than being derived from crude oil, is 100%

immune from thermal viscosity breakdown. So remember, it's very important

to keep the oil changed regularly, keep the cooling fins that's on the

hydrostatic pump/motor clean and free of debris, make sure the fan that blows

cooling air over the hydrostatic pump/motor is in good, working condition,

and perform thorough routine maintenance at least once a year before using

the tractor or equipment, and the hydrostatic unit will probably last forever.

By the way - it takes approximately 7 quarts of oil to fill the Cub Cadet

garden tractor hydrostatic drive transaxle and filter.

A non-synthetic oil will provide superior lubrication as long as you keep the cooling fins and hydrostatic drive areas clean and free of grass and debris. Make sure the fan on the driveshaft is in good condition, too. Clean the fins and hydrostatic drive areas the beginning of every year and the hydrostatic drive system should last a lifetime. Return to [Top of Page]. È

Information About the Cub Cadet Garden Tractor Creeper Drives - [Top of Page]

The Cub Cadet garden tractor

creeper drive is a 2-speed selective high/low gearbox. It's a small gearbox

that mounts on the front of the Cub Cadet garden tractor transaxle. When

the lever is placed in LOW position (reduction speed; 2:1 ratio), all the

gears in the transaxle are reduced by half, which means the tractor will

move half its speed, in forward and reverse. When the lever is placed in

HIGH position (1:1 ratio), the gears in the transaxle turn their normal speeds.

Creeper drives are required when mowing heavy grass, plowing a garden, pushing

snow or hauling heavy loads up a steep hill, doing all this especially with

a small engine and for safety.

The Cub Cadet garden tractor

creeper drive is a 2-speed selective high/low gearbox. It's a small gearbox

that mounts on the front of the Cub Cadet garden tractor transaxle. When

the lever is placed in LOW position (reduction speed; 2:1 ratio), all the

gears in the transaxle are reduced by half, which means the tractor will

move half its speed, in forward and reverse. When the lever is placed in

HIGH position (1:1 ratio), the gears in the transaxle turn their normal speeds.

Creeper drives are required when mowing heavy grass, plowing a garden, pushing

snow or hauling heavy loads up a steep hill, doing all this especially with

a small engine and for safety.

The creeper drive was optional equipment that was offered by Cub Cadet. The same cast iron housing creeper drive fits all models of clutch drive IH and MTD Cub Cadet garden tractors, except the IH Cub Cadet "Original" garden tractor. This unit will fit models 70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126, 128, 582, 800, 1000, 1050, 1200, 1535, 1604, 1606 and 1806. A shorter driveshaft is required with a creeper drive.

If your tractor didn't come with a creeper drive and you wish to install one, here's how to do it: (This is much easier to do on a platform work table.)

Remove

the driveshaft/clutch assembly and rear driveshaft coupler from the

tractor.

Remove

the driveshaft/clutch assembly and rear driveshaft coupler from the

tractor.

NOTE: The official Cub Cadet (MTD) repair manual says that upon reassembly of the MTD-built creeper drive, pack it with 14 oz. of grease. But grease gets slung away from fast spinning parts, leaving the moving parts with a thin coating of grease with very little lubrication for the life of the unit. Being this unit has a rubber O-ring seal, oil seal and gaskets, for smoother operation of the gears that operate under extreme pressure and for less wear to the moving parts, drill and tap an 1/8" NPT [oil level/check] hole for an 1/8" NPT tapered plug on the side of the housing opposite of the shift lever just below the level of the oil seal. And after installing the unit on the transaxle, fill it with SAE 90 weight gear oil through the breather tube opening on top until it runs out the oil level/check side hole on the side. Then replace the side plug and breather cap.

Also, the MTD-built creeper drive will fit and bolt right up to the older IH-built Cub Cadet garden tractor transaxles (except the IH Cub Cadet "Original" garden tractor), but the upper part of the tractor frame on models 70, 71, 72, 73 and 100 will need to be modified to accommodate the taller MTD-built creeper drive housing and the driveshaft will need to be shortened by 4-3/4".

And as with all transmissions, transaxles, creeper drives and gear boxes, before shifting from one gear into another, ALWAYS bring the tractor or vehicle to a full complete stop with the clutch pedal fully depressed or the engaging lever fully disengaged to allow the gears to stop spinning and to avoid "grinding of the gears," which could break or wear the gear teeth or engaging splines.

Advertisement: (Prices are subject to change without notice.)

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | |||||||

Neoprene Rubber O-Ring Seals -

|

|||||||

A-1 Miller's Professional

Repair/Rebuild Services - A-1 Miller's Professional

Repair/Rebuild Services -

Repair or Rebuild IH- or MTD-built Cub Cadet Garden Tractor Creeper Drive. $75.00 labor only, plus return shipping & handling. Installation of new parts (shown above) are extra charge. MTD-built Cub Cadet Creeper Drive only - Install Oil Level Check Plug on Side and Oil Drain Plug on Bottom in so it can be filled with 90 weight gear oil (instead of being 100% sealed and packed with factory-recommended grease) so parts inside will last much longer. $30.00 extra for parts and labor, plus return shipping & handling. |

Gearing a Cub Cadet Competition Garden Pulling Tractor - [Top of Page]

In tractor pulling, understanding the concept of having the correct gearing to achieve adequate ground speed so the engine will have enough power to spin the tires on any given track conditions can be a challenge. Overdrive and underdrive gears either speed up or slow down the transmission gears in the transaxle. And by changing the transmission gears, this will give the puller a choice of slower or faster gears according to track conditions.

Having very slow ground speed or very high ground speed can sometimes hurt how well a tractor can pull. With a healthy engine, at the end of the track, if the engine is still revving like there's no load on it, then this means the gearing is too low. But if the engine bogs down and die, this means the gearing is too high. In other words, the gearing needs to be "balanced" to the strength of the engine so when the sled's weight is on the tractor (entire weight of tractor transferred over the rear tires), the tires will still spin some, but the engine will bog down slightly.

The reason to use the right gearing in a pulling tractor is to match an engine's ability to give the tractor momentum so it can pull the sled a little further down the track without sacrificing horsepower or increasing/decreasing torque at the rear wheels. In other words, if one pulls in a particular gear that is too fast, they increase the ground speed, but run out of horsepower in the end. If they pull in a gear that's too slow, they have plenty of power, but don't have the needed ground speed, meaning they may run out of traction at the end. The point here is to obtain a correct "balance" between an engines' power output and torque at its rear tires, which should result in a good pull every time.

The teeth count of the upper and lower forward gears in a Cub Cadet transaxle must total 52 (example: 19t upper gear + 33t lower gear = 52 teeth total). Otherwise, if they don't total up to 52, one gear will be too big and the other too small, and the teeth won't mesh (engage) correctly. When referring to which gears are in a tractor, all pullers refer to the teeth count on the upper gears only. To count the teeth on the upper gear only, remove the shifter lever cover from the transaxle, and place a paint mark on one tooth (as reference for the starting point), then rotate the gear and count the rest of the teeth.

To find the gear ratio, always divide the number of teeth on the lower gear by the number of teeth on the upper gear. Place a mark on one tooth, then count the other teeth until you get back to the mark. The mating upper and lower gears together have a total of 52 teeth. There are no exceptions. For example: 2nd speed has 19 teeth on the upper gear and 33 teeth on the lower gear to equal 52 teeth total (19 + 33 = 52). And 3rd speed have two 26 tooth gears, resulting in a total of 52 teeth (26 + 26 = 52). And so forth. Factory stock OEM (Original Equipment Manufacturer) gear ratios are as follows:

The factory-installed gears that originally came in IH Cub Cadet transaxles (a "transaxle" is the union of a transmission and rear axle in one case) are 13 tooth 1st gear, 16, 17 or 19 tooth 2nd gear and 26 tooth 3rd gear. The "tooth" count are the number of teeth on each upper gear. The 16 tooth 2nd came out in the early 1960's, while the 17 and 19 tooth replaced it in later years.

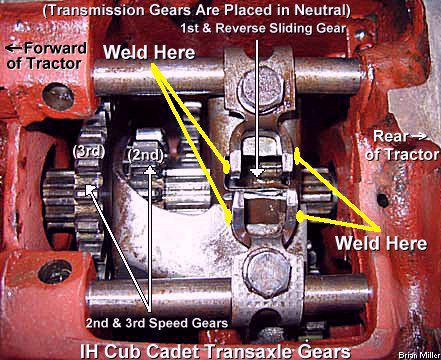

The OEM (Original Equipment Manufacturer) Cub Cadet 2nd and 3rd upper sliding gears are made together, next to each other. This is why they're called cluster gears. They have the 2nd/3rd speed shift fork between them. The 2nd and 3rd bottom gears are separate, fixed in place, and is spaced apart with a spacer. And 1st sliding gear is used for forward and reverse. The 1st/Reverse shift fork fits over 1st gear. Cub Cadet garden tractors originally came with 16, 17 and 19 tooth second gears. (This is the upper sliding cluster 2nd speed gear; upper 3rd speed gear is 26 tooth in all models.)

The number of factors to take into consideration when choosing the right gearing for a garden pulling tractor are:

If a pulling club's rules require that 23-10.50x12 [Carlisle Super Lug or Vogel] tires to be used, then these tires can be mounted on 12" wide wheels. I've seen this done many times on pulling tractors with great results. The wider wheels will allow the tire tread to lay flatter for better traction, but it'll also shorten the overall tire height slightly which will reduce the tractor's ground speed. Therefore, to regain the ground speed, if it's a Cub Cadet, perhaps installing 10% overdrive gears should do the trick. Also, 23-10.50x12 inner tubes may need to be installed to get the tire(s) to take air due to the wider wheels and narrow tires.

Rule of thumb in choosing the

right gear ratios are as follows: NOTE: The following statements

are meant only as a reference. The right gearing depends mainly on the strength

and/or size of the engine and track conditions. And when it comes to competition

pulling, nothing is really certain. Weights shown is with driver.

Rule of thumb in choosing the

right gear ratios are as follows: NOTE: The following statements

are meant only as a reference. The right gearing depends mainly on the strength

and/or size of the engine and track conditions. And when it comes to competition

pulling, nothing is really certain. Weights shown is with driver.

The

OEM Cub Cadet 12 tooth pinion drive gear/shaft can be swapped out with an

aftermarket 13 tooth pinion drive gear/shaft and the OEM 84 tooth lower driven

gear can be reused. This will increase the drive gears about 1 tooth, resulting

in about a 5% increase in ground speed.

The

OEM Cub Cadet 12 tooth pinion drive gear/shaft can be swapped out with an

aftermarket 13 tooth pinion drive gear/shaft and the OEM 84 tooth lower driven

gear can be reused. This will increase the drive gears about 1 tooth, resulting

in about a 5% increase in ground speed.

But if you want your tractor

to go even faster than the above mentioned, then both the upper and lower

gears in the transmission must be changed. The reason for a combination

2nd and 3rd speed gear set is to slow down the tires

in 2nd gear when pulling on a biting track (moistened and packed

surface), which will provide more traction and reserve engine power/torque,

because the tires probably wouldn't be able to spin as easily. And with a

slightly faster 3rd gear, (faster than the OEM 2nd

gear, but slower than factory stock 26 tooth 3rd gear), would

perform better on a hard, dry or loose track, which will allow the tires

to spin more easily, will provide more ground speed without sacrificing engine

power/torque. So having a double gear set is better than pulling in just

one gear (2nd or perhaps 1st) all the time, which is

either too slow or too fast.

But if you want your tractor

to go even faster than the above mentioned, then both the upper and lower

gears in the transmission must be changed. The reason for a combination

2nd and 3rd speed gear set is to slow down the tires

in 2nd gear when pulling on a biting track (moistened and packed

surface), which will provide more traction and reserve engine power/torque,

because the tires probably wouldn't be able to spin as easily. And with a

slightly faster 3rd gear, (faster than the OEM 2nd

gear, but slower than factory stock 26 tooth 3rd gear), would

perform better on a hard, dry or loose track, which will allow the tires

to spin more easily, will provide more ground speed without sacrificing engine

power/torque. So having a double gear set is better than pulling in just

one gear (2nd or perhaps 1st) all the time, which is

either too slow or too fast.

To replace the input shaft/pinion drive gear, first remove the cover from the reduction gear housing, and use a medium size hammer and deepwell socket that fits inside the needle bearing housing on the back-side of the reduction gear housing, and drive out the input shaft/pinion gear from the rear of the housing. The oil seal, shaft/gear and needle bearing will all come out as one unit. After the new shaft is installed, apply a thin bead of clear RTV silicone adhesive sealant to seal the bearing in the rear of the housing. By the way - it's best to use Clear RTV Silicone Adhesive Sealant for three reasons: Gaskets don't always seal the imperfections and irregularities between two mating metals, especially thin metal covers; being Clear RTV Silicone Adhesive Sealant is an adhesive or glue, it bonds parts together, forming a leak-proof seal; and being it's clear, it makes for a clean and professional-looking repair job. When applied sparingly, it can't be easily seen or noticed between the parts. Also, engine heat has very little effect on silicone rubber. It can withstand up to 2,500 degrees heat.

Or, to remove a pinion and not destroy any parts (seal, etc.) use a "slide hammer" and put an angle or channel steel to use as a lever. Using this method, you do not damage even the most stubborn pinion. You can reuse everything and don't have to worry about any leaks.

No machine work is required when installing overdrive gears. But some grinding inside the housing may be required when installing a large pinion drive gear. Otherwise, just remove the pinion drive gear and the lower driven gear and install the aftermarket gears in the reverse order of removal.

And when reassembling a Cub Cadet gear drive transaxle, there's no need to install any high-dollar gaskets that are prone to leaking oil. Instead, apply a thin bead of clear RTV silicone adhesive sealant to reassemble the entire transaxle case. Silicone rubber is what I've always used on my transaxles since 1989 and to this day, they haven't leaked a drop of oil. And by eliminating gaskets, the use of silicone "strengthens" the transaxle housings by securely "bonding" them together or having them make positive metal-to-metal contact, which keeps the bolts securely tight, plus the silicone fills in any irregularities or imperfections between the two metals, eliminating oil leaks. By the way - it's best to use Clear RTV Silicone Adhesive Sealant for three reasons: Gaskets don't always seal the imperfections and irregularities between two mating metals, especially thin metal covers; being Clear RTV Silicone Adhesive Sealant is an adhesive or glue, it bonds parts together, forming a leak-proof seal; and being it's clear, it makes for a clean and professional-looking repair job. When applied sparingly, it can't be easily seen or noticed between the parts. Also, engine heat has very little effect on silicone rubber. It can withstand up to 2,500 degrees heat.

FYI - If oil leaks from an engine, transmission/transaxle or steering box, causing an oily mess on a concrete floor, mineral spirits (paint thinner) can be used to dry out the oil. Just pour some thinner on the oil, use an old broom to thoroughly mix the thinner with the oil, and eventually the oil will dry with no signs of it ever being on the floor. Because of its low volatile flammability, paint thinner also works great as a cleaning solvent, which is used to clean oily or greasy mechanical parts.

Fabricate a Simple, yet Functional Shift Lever Lock (to prevent the tractor from "jumping out of gear" when pulling) -

If you're using

either old or new gears, due to severe stress that pulling places on the

gears, it's always a good idea to install a sturdy shifter lock on

the tractor frame to hold the lever in gear when pulling. If pulling in just

2nd gear only, an

adjustable yoke end can be used, or a short U-shape shifter

lock can be made of minimum 1/8" thickness x 1" wide aluminum or steel. But

when pulling in only 2nd and 3rd gears, or with in

4 forward gear setup with no reverse, make the U-shape shifter lock taller

and tilted back so it'll be at a 90º angle with the shift lever for

positive locking (causing no movement) of the lever. Use two 1/4" bolts to

fasten the U-shape shifter lock to the tractor frame. The shift lever will

need to be in place on the tractor to properly align the pins in the shifter

lock and fasten the shifter lock bracket to the tractor frame in the right

spot. To ensure that the mating top and bottom gears are perfectly aligned

and fully engaged, and to prevent misalignment of the gears when they are

locked in position, accurately measure (twice), cut (once) and drill the

holes (once) before fabricating, welding and permanently installing the U-shape

shifter lock!

If you're using

either old or new gears, due to severe stress that pulling places on the

gears, it's always a good idea to install a sturdy shifter lock on

the tractor frame to hold the lever in gear when pulling. If pulling in just

2nd gear only, an

adjustable yoke end can be used, or a short U-shape shifter

lock can be made of minimum 1/8" thickness x 1" wide aluminum or steel. But

when pulling in only 2nd and 3rd gears, or with in

4 forward gear setup with no reverse, make the U-shape shifter lock taller

and tilted back so it'll be at a 90º angle with the shift lever for

positive locking (causing no movement) of the lever. Use two 1/4" bolts to

fasten the U-shape shifter lock to the tractor frame. The shift lever will

need to be in place on the tractor to properly align the pins in the shifter

lock and fasten the shifter lock bracket to the tractor frame in the right

spot. To ensure that the mating top and bottom gears are perfectly aligned

and fully engaged, and to prevent misalignment of the gears when they are

locked in position, accurately measure (twice), cut (once) and drill the

holes (once) before fabricating, welding and permanently installing the U-shape

shifter lock!

When pulling competitively, it's best to lock the shift lever in gear despite the best gears/shafts/bearing retainers installed and if the gears are properly aligned. Because sometimes they'll still jump out of gear under hard pulling pressure. I believe there's no bigger disappointment and embarrassment than having your tractor jump out of gear on the track, especially when you knew there was a chance that it would jump out of jump.

When building a Cub Cadet garden tractor from scratch (parts from other Cub Cadet garden tractors), remember - there's differences between the shift levers on IH-built Cub Cadets. Models IH Cub Cadet "Original" garden tractor, Cub Cadet garden tractor models 70, 71, 72 and 100 use the same shift lever (part # IH-376214-R12). Models 73, 106 and 126 use the same shift lever (part # IH-528881-R1). Models 102, 104, 122 and 124 use the same shift lever (part # IH-392628-R11). And models 86, 108, 128, 582 (IH), 800, 1000 and 1200 use the same shift lever (part # IH-544135-R1).

Sometimes

while the tractor is connected to a heavy trailer, or still hooked to the

sled just after a pull, the clutch(es) on a Cub

Cadet will refuse to release (with the clutch pedal fully depressed, of course)

and at the same time the puller/operator tries to force the shift lever into

the neutral position, this may cause the transmission gears to become locked

up.

Sometimes

while the tractor is connected to a heavy trailer, or still hooked to the

sled just after a pull, the clutch(es) on a Cub

Cadet will refuse to release (with the clutch pedal fully depressed, of course)

and at the same time the puller/operator tries to force the shift lever into

the neutral position, this may cause the transmission gears to become locked

up.

If this has happens, to fix this, first, the entire transaxle will need to be removed from the tractor's frame (this is much easier to do on a platform work table), or just move it back enough so the shift lever cover can be removed. After that, use a large flat screwdriver to shift the gears into the neutral position. (That's when the slots in the shift forks [where the shift lever ball end fits into] are aligned.) Then, you'll notice that the shifter forks are flared out. Use a hammer to bring them back together so the shift lever ball will fit snugly into them. Due to worn gears and pulling force, these slots will sometimes flare out on their own.

Shifter forks get broken, too. I've welded many of them back together with success. And if they don't break, they get bent from someone trying to jam or force the shift lever into gear when the tractor is sitting still with two gear teeth aligned and not offset with each other. This is when the operator needs to lightly engage the clutch or physically roll the tractor back and forth to get the gear teeth offset so the shift lever will go into gear. The same thing needs to be done with a car, truck or anything that has a manual shift transmission or transaxle to prevent damage.

To replace a broken shifter fork, first, remove the rod it attaches to. To do so, remove the transaxle from the tractor (this is much easier to do when using a platform work table), remove the front gear reduction housing, remove the rear end cover, then use a long drift (3/8" bendable steel rod) to drive the shifter rod forward from the transaxle case. Be sure to place a finger over the hole so the small steel ball and spring won't pop out and possibly get lost. Reassembly is in reverse order of removal.

To prevent the

gears from locking up again, first, make sure that the slots are properly

aligned and they're not flared out. Then place a bead of weld on each side

of the shift forks as shown in the photo to the right -> so they won't

spread out again. The weld will prevent the slots from spreading again and

also keep the clamp bolts from loosening.

To prevent the

gears from locking up again, first, make sure that the slots are properly

aligned and they're not flared out. Then place a bead of weld on each side

of the shift forks as shown in the photo to the right -> so they won't

spread out again. The weld will prevent the slots from spreading again and

also keep the clamp bolts from loosening.

And in high-torque engine tractors, the mainshaft (upper shaft) could become twisted, resulting in total lock up of all the gears. Contact A-1 Miller's Performance Enterprises for quality hardened gears, shafts, ring gears and other Cub Cadet transaxle components.

The Cause for Reverse to "Jump Out" of Gear -

If the transaxle jumps out of reverse, especially when backing up a slight grade (hill), this means either the shift forks are bent and need straightening and welding. Or the gear teeth on the reverse idler are worn and the gear itself needs to be replaced. The gear teeth on the 1st/reverse sliding gear suffers the same abuse, so it should be replaced, too. What cause this is when the operator don't come to a full stop before shifting into reverse. Instead, they grind the transmission into reverse, which wears off the gear teeth. The gear teeth loses their "squareness," and cannot stay engaged correctly. The same thing happens with the reverse idler gear in automotive transmissions. To replace the reverse idler and 1st/reverse gears, the entire transmission or transaxle must be completely disassembled. There is no other way to fix this.

By the way - all IH gear drive transaxles use the same shifter forks from the IH Cub Cadet "Original" garden tractor until MTD made the 3 piece aluminum case. And you use caution if using an aluminum housing transaxle for competitive pulling. Aluminum don't have the strength that the cast iron ones does. When pressure is applied to the housing (the gears pushing against each other under stress; the housing is what holds the gears together), the aluminum housing will sometimes crack or break.

Advertisement: (Prices are subject to change without notice.)

| Click here to contact A-1 Miller's Performance Enterprises to place an order, send your parts for repairing, and/or for FREE professional and honest technical customer service assistance and support and payment options. Please contact A-1 Miller's if you need a part or parts, or service(s) performed that's not listed or mentioned in this website. | |

A-1 Miller's

Professional Repair Service - Repair your broken or "sloppy" IH Cub Cadet

garden tractor shifter assembly. NOTE: When sending your broken shafter

assembly to A-1 Miller's, please include the shift lever and shifter housing

so when performing the repair, the shift lever will be properly aligned with

the housing. A-1 Miller's

Professional Repair Service - Repair your broken or "sloppy" IH Cub Cadet

garden tractor shifter assembly. NOTE: When sending your broken shafter

assembly to A-1 Miller's, please include the shift lever and shifter housing

so when performing the repair, the shift lever will be properly aligned with

the housing.

|

|

Shift Rail Steel Detent Ball and Detent Spring. Each part below

fits all gear-drive transaxles in Cub Cadet garden tractor models 70, 71,

72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126, 128, 580, 582, 800, 1000,

1050, 1200, 1220, 1320, 1330, 1420, 1535, 1604, 1606, 1720, 1730 and 1806. Shift Rail Steel Detent Ball and Detent Spring. Each part below

fits all gear-drive transaxles in Cub Cadet garden tractor models 70, 71,

72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126, 128, 580, 582, 800, 1000,

1050, 1200, 1220, 1320, 1330, 1420, 1535, 1604, 1606, 1720, 1730 and 1806.

|

|

Oil Seals.

Fits Cub Cadet Garden Tractor Reduction Housing Input Pinion Shaft/Gears

(above È).

IMPORTANT - Before installing

any new seal, always apply oil or fiber-free grease inside the seal and on

the shaft to keep the rubber lubricated and cool until internal oil can reach

it. With no prior lubrication, the dry rubber will wear away from friction,

causing another oil leak. Do the job right the first time, and it won't have

to be done again for a long time. Oil Seals.

Fits Cub Cadet Garden Tractor Reduction Housing Input Pinion Shaft/Gears

(above È).

IMPORTANT - Before installing

any new seal, always apply oil or fiber-free grease inside the seal and on

the shaft to keep the rubber lubricated and cool until internal oil can reach

it. With no prior lubrication, the dry rubber will wear away from friction,

causing another oil leak. Do the job right the first time, and it won't have

to be done again for a long time.

Oil Seal. Fits IH Cub Cadet "Original" Input Shaft/Gear. Dimensions: 3/4" I.D. x 1.756" O.D. x 3/8" height. High quality aftermarket. Replaces discontinued Cub Cadet part # IH-377959-R91. $16.00 each, plus shipping & handling. Oil Seals. Fits IH-built Cub Cadet Cast Iron Housing Reduction Housing Input Pinion Shaft/Gear.

Oil Seal. Fits MTD-built Cub Cadet Aluminum Housing Reduction Housing Input Pinion Shaft/Gear. Dimensions: 5/8" I.D. x 1.574" O.D. x 5/16" height. High quality aftermarket. Replaces discontinued Cub Cadet part # 721-0193. $16.00 each, plus shipping & handling. |

|

External Bearing

Retainer Compression/Snap Ring. Fits OEM Cub Cadet and aftermarket .667"/17mm

diameter input pinion shaft with an integrated 10, 11, 12, 13, 14 or 15 tooth

drive gear. Made of high strength carbon steel. High quality aftermarket.

Replaces discontinued Cub Cadet part #'s IH-384709-R1 and 716-0143. External Bearing

Retainer Compression/Snap Ring. Fits OEM Cub Cadet and aftermarket .667"/17mm

diameter input pinion shaft with an integrated 10, 11, 12, 13, 14 or 15 tooth

drive gear. Made of high strength carbon steel. High quality aftermarket.

Replaces discontinued Cub Cadet part #'s IH-384709-R1 and 716-0143.

External Bearing Retainer Compression/Snap Ring. Fits aftermarket 5/8" diameter splined input pinion shaft with a slide-on 16 or 17 tooth drive gear. Made of high strength carbon steel.

|

|

High-Speed Precision

Radial Ball Bearings. Fits IH- and MTD-built Cub Cadet cast iron and aluminum

gear reduction housings with OEM and aftermarket overdrive and underdrive

input pinion shaft with the integrated pinion gear and slide-on pinion gear.

Dimensions: .667"/17mm I.D. x 1.575"/40mm O.D. x .470"/12mm height. FYI

- All ball bearings have always been made to the metric dimensions. Where

applicable, the US and import manufacturers try to make them close to the

inch dimensions as possible. High-Speed Precision

Radial Ball Bearings. Fits IH- and MTD-built Cub Cadet cast iron and aluminum

gear reduction housings with OEM and aftermarket overdrive and underdrive

input pinion shaft with the integrated pinion gear and slide-on pinion gear.

Dimensions: .667"/17mm I.D. x 1.575"/40mm O.D. x .470"/12mm height. FYI

- All ball bearings have always been made to the metric dimensions. Where

applicable, the US and import manufacturers try to make them close to the

inch dimensions as possible.

|

|

Closed-End Needle

Bearing. Fits input shaft/pinion gear in transaxle of all clutch drive IH-

and MTD-built Cub Cadet garden tractors. Closed-End Needle

Bearing. Fits input shaft/pinion gear in transaxle of all clutch drive IH-

and MTD-built Cub Cadet garden tractors.

|

|

|

One Piece Input

Shafts w/Integrated 12 Tooth Pinion Drive Gear. Each have an unworn spiral

pin hole. Each input shaft listed below fits Cub Cadet garden tractor models

70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126, 128, 580, 582,

800, 1000, 1050, 1200, 1535, 1604, 1606 and 1806, except models 1250, 1450

and 1650 with a hydrostatic disconnect attachment. One Piece Input

Shafts w/Integrated 12 Tooth Pinion Drive Gear. Each have an unworn spiral

pin hole. Each input shaft listed below fits Cub Cadet garden tractor models

70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124, 126, 128, 580, 582,

800, 1000, 1050, 1200, 1535, 1604, 1606 and 1806, except models 1250, 1450

and 1650 with a hydrostatic disconnect attachment.

|

|

One Piece Input

Shaft and Integrated 5%/13 Tooth Overdrive Pinion Drive Gear. Fits Cub Cadet

garden tractor models 70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124,

126, 128, 580, 582, 800, 1000, 1050, 1200, 1535, 1604, 1606 and 1806. Speeds

up all transmission gears about one tooth about 5% for more ground speed.

1.241" diameter gear; use only with OEM Cub Cadet garden tractor 84 tooth

lower driven gear. Intended mainly for competition pulling, but can be used

for general lawn and garden work to slightly speed up tractor. Uses OEM .667"

/ 17mm ball bearing. NOTE: This is NOT the same as the 13 tooth pinion gear

that's used with the 10% and 26% overdrive gears listed below. They have

a different diameter. Made by True Gear & Spline. $122.00 each,

plus shipping & handling. One Piece Input

Shaft and Integrated 5%/13 Tooth Overdrive Pinion Drive Gear. Fits Cub Cadet

garden tractor models 70, 71, 72, 73, 86, 100, 102, 104, 106, 108, 122, 124,

126, 128, 580, 582, 800, 1000, 1050, 1200, 1535, 1604, 1606 and 1806. Speeds

up all transmission gears about one tooth about 5% for more ground speed.

1.241" diameter gear; use only with OEM Cub Cadet garden tractor 84 tooth

lower driven gear. Intended mainly for competition pulling, but can be used

for general lawn and garden work to slightly speed up tractor. Uses OEM .667"

/ 17mm ball bearing. NOTE: This is NOT the same as the 13 tooth pinion gear

that's used with the 10% and 26% overdrive gears listed below. They have

a different diameter. Made by True Gear & Spline. $122.00 each,

plus shipping & handling.

Replacement Splined Input Shaft for the 26%, 33%, 38%, 43% and 47% overdrive gears that accept the 13, 14, 15, 16 and 17 tooth slide-on pinion drive gears. Replace worn beyond specifications or damaged input shaft to match an overdrive and underdrive lower gears listed below. Uses same bearing, oil seal and retaining ring as OEM input shaft. Made by True Gear & Spline. $142.00 each, plus shipping & handling.

Constant Mesh Overdrive and Underdrive Reduction Drive Gear Sets. Fits IH/MTD Cub Cadet Garden Tractor Transaxles. Precision CNC-ground, hardened, heat-treated and hardened gears. Smooth operation with no rattle or gear teeth clatter. The OEM 12 tooth input pinion gear can be replaced with a 13 tooth/5% pinion gear without replacing the bottom larger gear. For faster speeds, the OEM 12 tooth input pinion and reduction gears can be replaced with either 10%, 16%, 23%, 26%, 33%, 38%, 43% or 47% aftermarket overdrive pinion and reduction gears, or 10% and 20% underdrive pinion and reduction gears. The percentage is the amount the tractor speed is increased or decreased. Intended for competition pulling, but can be used for general lawn and garden work to speed up or slow down tractor. Made by True Gear & Spline. Use this Cub Cadet Gear Ratio Chart to determine which gears your tractor needs. (Open with Microsoft Excel or OpenOffice Calc and use Google Chrome web browser for a faster download of websites with large files.)

Underdrive Gear Sets. Decrease gear ratio for less ground speed.

|

|

1st and Reverse 13 Tooth

Sliding Gear. Replace OEM gear with worn teeth to prevent tractor from jumping

out of reverse when backing up a heavy trailer, hill or ramp. Fits all IH-

and MTD-built Cub Cadet garden tractor clutch drive garden tractors, Cub

Lo-Boy models 154, 184 and 185, International Cub, Farmall Cub and Farmall

Cub Lo-Boy. New. High quality aftermarket. Not made by True Gear & Spline.

Replaces discontinued Cub Cadet part # 917-3078. $75.00 each, plus

shipping & handling. 1st and Reverse 13 Tooth

Sliding Gear. Replace OEM gear with worn teeth to prevent tractor from jumping

out of reverse when backing up a heavy trailer, hill or ramp. Fits all IH-

and MTD-built Cub Cadet garden tractor clutch drive garden tractors, Cub

Lo-Boy models 154, 184 and 185, International Cub, Farmall Cub and Farmall

Cub Lo-Boy. New. High quality aftermarket. Not made by True Gear & Spline.

Replaces discontinued Cub Cadet part # 917-3078. $75.00 each, plus

shipping & handling. |

Reverse Idler 22 Tooth Gear

w/Bronze Bushing. Replace OEM gear with worn teeth to prevent tractor from

jumping out of reverse when backing up a hill or ramp. Fits all IH- and MTD-built

Cub Cadet garden tractor clutch drive garden tractors, Cub Lo-Boy models

154, 184 and 185, International Cub, Farmall Cub and Farmall Cub Lo-Boy.

New. High quality aftermarket. Not made by True Gear & Spline. Replaces

discontinued Cub Cadet part # 917-3188. $75.00 each, plus shipping

& handling. Reverse Idler 22 Tooth Gear

w/Bronze Bushing. Replace OEM gear with worn teeth to prevent tractor from

jumping out of reverse when backing up a hill or ramp. Fits all IH- and MTD-built

Cub Cadet garden tractor clutch drive garden tractors, Cub Lo-Boy models

154, 184 and 185, International Cub, Farmall Cub and Farmall Cub Lo-Boy.

New. High quality aftermarket. Not made by True Gear & Spline. Replaces

discontinued Cub Cadet part # 917-3188. $75.00 each, plus shipping

& handling. |

Custom Upper

Cluster Slider Gears and Two Lower Stationary Gears. Fits IH/MTD Cub Cadet

garden tractor transaxles. Precision CNC-ground, hardened, heat-treated gears.

Smooth engagement with no rattle or gear teeth clatter. Gear sets include

one upper cluster (two gears made together) gears and two separate lower

gears. Intended for competition pulling, but can be used for general lawn

and garden work to speed up or slow down tractor in any particular gear.

Made by True Gear and Spline. Custom Upper

Cluster Slider Gears and Two Lower Stationary Gears. Fits IH/MTD Cub Cadet

garden tractor transaxles. Precision CNC-ground, hardened, heat-treated gears.

Smooth engagement with no rattle or gear teeth clatter. Gear sets include

one upper cluster (two gears made together) gears and two separate lower

gears. Intended for competition pulling, but can be used for general lawn

and garden work to speed up or slow down tractor in any particular gear.

Made by True Gear and Spline.

FYI - The Cub Cadet garden tractor transaxle can be converted with 3 forward speed gears by swapping out the 1st, 2nd and 3rd speed gears, and retain reverse gear. Or it can be converted with 4 forward speed gears with no reverse gear. Listed are the most popular gear sets: (Upper teeth count.) 14/15, 14/16, 15/16, 15/17, 16/17, 16/18, 17/18, 17/19, 18/19, 18/20, 19/20, 19/21, 20/21, 20/22, 21/22, 21/23, 22/23, 22/24, 23/24, 23/25, 24/25, 24/26, 25/26, 25/27, 26/27. Other gear sets are also available; from 13 teeth to 28 teeth in any combination you desire. Tooth count on one upper cluster gear and matching bottom gear must add up to 52. Exception: for the upper 13 tooth cluster gear, reuse the OEM Cub Cadet 39 tooth lower (1st speed) lower gear. Use this Cub Cadet Gear Ratio Chart to determine which gears your tractor needs. If you wish to use a faster gear than the 28 tooth, then an overdrive gear set (listed above) will also need to be used. Any combination. $203.00 per set, plus shipping & handling. Custom Gears Installation Information: The True Gear 2nd and 3rd gear set lower gears are wider than the Cub Cadet OEM lower gears. Therefore, the cone-shape spacer at the front of the lower pinion shaft will need to be narrowed about .050" so the pinion gear will mesh correctly with the ring gear. Exception: for the 13 tooth cluster gear, reuse the OEM Cub Cadet 39 tooth bottom gear. And if the upper gears are larger in diameter than the OEM gears, the shifter fork may need grinding for clearance. Or if the gears are really big, a billet shifter fork will need to be installed. Otherwise, 1st and reverse gears and everything else should remain the same in the transaxle. |

|

| Use this interactive

Cub Cadet Gear Ratio Chart or

the chart below Ê to determine which

gears your tractor may need. (Open this linked file with either

Microsoft

Excel or

OpenOffice

Calc and use

Google

Chrome web browser for a faster download of websites with large

files.) Remember - there's about a 600

RPM difference (reduction or increase) in gearing between one set of gears

with a particular number of teeth and another set of gears with one tooth

more or one tooth less.

|

|

Top Shafts.

Fits IH-Built Cub Cadet Garden Tractors with the Gear-Drive Cast Iron Housing

Transaxle. This is the upper splined shaft for the sliding 1st/reverse and

2nd/3rd gears. Will not fit the MTD-built Cub Cadet garden tractors with

the aluminum housing transaxle. Top Shafts.

Fits IH-Built Cub Cadet Garden Tractors with the Gear-Drive Cast Iron Housing

Transaxle. This is the upper splined shaft for the sliding 1st/reverse and

2nd/3rd gears. Will not fit the MTD-built Cub Cadet garden tractors with

the aluminum housing transaxle.

|

|

| OEM Cub Cadet and Heavy Duty Aftermarket Ring and Pinion

Gear Sets. Fits IH-Built Cub Cadet garden tractor transaxles - NOTE: The

IH-built Cub Cadet garden tractor cast iron transaxle housing ring and pinion

gears will not fit the MTD-built Cub Cadet garden tractor aluminum transaxle

housing. Also, the OEM IH Cub Cadet ring or pinion gears will not properly

engage or mesh with True Gear's heavy duty ring or pinion gears. Neither

can be used with True Gear ring and pinions because True Gear ring and pinions

have additional metal in the gear teeth area to hold up to the extreme stress

of pulling. And all IH-built Cub Cadet and True Gear ring and pinion

gear sets have a 4.6:1 ratio.

OEM IH Cub Cadet Ring Gear ONLY. Fits Cub Cadet "Original", all IH-Built Cub Cadet garden tractors, Cub Lo-Boy and Farmall Cub International. Made of extremely hardened, heat-treated high quality steel. Used and in excellent condition with no chipped or broken teeth. Part of OEM Cub Cadet differential assembly, part # IH-350787-R1. No separate Cub Cadet part number available. $50.00 each, plus shipping & handling. (When available.) OEM IH Cub Cadet Pinion Countershaft and Bevel Gear ONLY for External (Axle) Brakes. (Shorter shaft w/o splines.) Made of extremely hardened, heat-treated high quality steel. Used and in excellent condition with no chipped or broken teeth. No Cub Cadet part number available. $50.00 each, plus shipping & handling. (When available.) OEM IH Cub Cadet Pinion Countershaft and Bevel Gear ONLY for an Internal Brake or External (Axle) Brakes. (Longer shaft w/splines.) Made of extremely hardened, heat-treated high quality steel. Used and in excellent condition with no chipped or broken teeth. No Cub Cadet part number available. $50.00 each, plus shipping & handling. (When available.) Heavy Duty True Gear Hardened Replacement Forward Cut Ring and Pinion Gear Set. For use with engines that turn clock-wise when facing the flywheel. Can be used with internal brake or external/axle brakes. Made of extremely hardened, heat-treated high quality steel. Inside diameter same as OEM Cub Cadet ring gear (4-1/2"). The centering ring is required to install this ring gear on the Chrysler carrier. $574.00 per set, plus shipping & handling. Heavy Duty True Gear Hardened Reverse Cut Ring and Pinion Gear Set. For use with a Diesel or reverse rotation engine in a Cub Cadet. No need to flip carrier. Can be used with internal brake or external/axle brakes. Made of extremely hardened, heat-treated high quality steel. Inside diameter same as OEM Cub Cadet ring gear (4-1/2"). The centering ring is required to install this ring gear on the Chrysler carrier. $864.00 per set, plus shipping & handling. |

|

IH-Built Cub Cadet

Garden Tractor IH-Built Cub Cadet

Garden Tractor  Light Duty, One

Piece "Thin Casting" Cast Iron Differential Carrier Assembly with Coarse

Spline Side (Spider) Gears. To be used with coarse spline axles (listed below).

Suitable for general lawn and garden usage, or in a competition pulling tractor

with 23x10.50-12 tires and 10" drawbar/hitch height. May break if used in

a competition pulling tractor with 26x12.00-12 size tires with a 13"

drawbar/hitch height. FYI - The bearings, ring gear and spider gears in

a thin-casting carrier will interchange with the thick-casting carrier and

MTD Cub Cadet fine spline carrier. Used and in excellent condition.

Discontinued Cub Cadet part # IH-350785-R92 (thin casting). Light Duty, One

Piece "Thin Casting" Cast Iron Differential Carrier Assembly with Coarse

Spline Side (Spider) Gears. To be used with coarse spline axles (listed below).

Suitable for general lawn and garden usage, or in a competition pulling tractor

with 23x10.50-12 tires and 10" drawbar/hitch height. May break if used in

a competition pulling tractor with 26x12.00-12 size tires with a 13"

drawbar/hitch height. FYI - The bearings, ring gear and spider gears in

a thin-casting carrier will interchange with the thick-casting carrier and

MTD Cub Cadet fine spline carrier. Used and in excellent condition.

Discontinued Cub Cadet part # IH-350785-R92 (thin casting).

IH-Built Cub Cadet  Garden Tractor

Heavy Duty, One Piece "Thick Casting" Cast Iron Differential Carrier Assembly

with Coarse Spline Side (Spider) Gears. To be used with coarse spline axles

(listed below). Suitable for general lawn and garden usage, or in a competition

pulling tractor with 23x10.50-12 tires and 10" drawbar/hitch height. May

break if used in a competition pulling tractor with 26x12.00-12 size tires

with a 13" drawbar/hitch height. FYI - The bearings, ring gear and spider

gears in a thin-casting carrier will interchange with the thick-casting carrier

and MTD Cub Cadet fine spline carrier. Used and in excellent condition.

Discontinued Cub Cadet part # IH-223472-C91 (thick casting). Garden Tractor

Heavy Duty, One Piece "Thick Casting" Cast Iron Differential Carrier Assembly

with Coarse Spline Side (Spider) Gears. To be used with coarse spline axles

(listed below). Suitable for general lawn and garden usage, or in a competition

pulling tractor with 23x10.50-12 tires and 10" drawbar/hitch height. May

break if used in a competition pulling tractor with 26x12.00-12 size tires

with a 13" drawbar/hitch height. FYI - The bearings, ring gear and spider

gears in a thin-casting carrier will interchange with the thick-casting carrier

and MTD Cub Cadet fine spline carrier. Used and in excellent condition.

Discontinued Cub Cadet part # IH-223472-C91 (thick casting).

NOTE: To remove the ring gear

from any of the above carriers, center-drill the rivets with a 1/4" drill

bit halfway through, then drive them out with a quality made 1/4" roll pin

punch and a big hammer. Then use 5/16-24 UNF Allen head bolts that measures

2" in nominal length (measured from under the head to the end of the threads)

with a 3/4" shank/shoulder (unthreaded part) with grade 8 nuts and split

lock washers. Torque the nuts to 25 ft. lbs. each to secure the ring gear

on the carrier. And cut/grind off the projected threaded part of each bolt

next to the nuts. NOTE: To remove the ring gear

from any of the above carriers, center-drill the rivets with a 1/4" drill

bit halfway through, then drive them out with a quality made 1/4" roll pin

punch and a big hammer. Then use 5/16-24 UNF Allen head bolts that measures

2" in nominal length (measured from under the head to the end of the threads)

with a 3/4" shank/shoulder (unthreaded part) with grade 8 nuts and split

lock washers. Torque the nuts to 25 ft. lbs. each to secure the ring gear

on the carrier. And cut/grind off the projected threaded part of each bolt

next to the nuts. |

|

Neoprene or Silicone

Rubber O-Ring Seal. Fits IH Cub Cadet "Original" Garden Tractor 3-Bolt Axle

Differential Bearing Flange. Dimensions: 3-1/8" I.D. x 3-3/8" O.D. x 1/8"

diameter. High quality aftermarket. Replaces discontinued Cub Cadet part

# IH-285723-R1. $2.50 each, plus shipping & handling. Neoprene or Silicone

Rubber O-Ring Seal. Fits IH Cub Cadet "Original" Garden Tractor 3-Bolt Axle

Differential Bearing Flange. Dimensions: 3-1/8" I.D. x 3-3/8" O.D. x 1/8"

diameter. High quality aftermarket. Replaces discontinued Cub Cadet part

# IH-285723-R1. $2.50 each, plus shipping & handling.

Oil Seal. Fits IH Cub Cadet "Original" Garden Tractor 3-Bolt Axle Pinion Bearing Flange. Dimensions: 1" I.D. x 1.830" O.D. x .296" thickness. High quality aftermarket. Replaces discontinued Cub Cadet part # IH-610465-C92. $15.00 each, plus shipping & handling. IMPORTANT - Before installing any new seal, always apply oil or fiber-free grease inside the seal and on the shaft to keep the rubber lubricated and cool until internal oil can reach it. With no prior lubrication, the dry rubber will wear away from friction, causing another oil leak. Do the job right the first time, and it won't have to be done again for a long time. |

|

Rear Axle Shaft

Oil Seal. Fits Peerless model 2300 4-speed transaxle with 1" diameter rear

axle shafts. Fits Cub Cadet belt drive garden tractor models 482, 580, 582

Special, 1100, and other makes and models of garden tractors with the Peerless

2300 transaxle. Direct replacement with no machining required. Dimensions:

1" I.D. x 1-3/8" O.D. x 1/4" thickness.

IMPORTANT - Before installing

any new seal, always apply oil or fiber-free grease inside the seal and on

the shaft to keep the rubber lubricated and cool until internal oil can reach

it. With no prior lubrication, the dry rubber will wear away from friction,

causing another oil leak. Do the job right the first time, and it won't have

to be done again for a long time. Replaces Tecumseh/Peerless part # 788008.

Our part # 252277. $10.00 each, plus shipping & handling. Rear Axle Shaft

Oil Seal. Fits Peerless model 2300 4-speed transaxle with 1" diameter rear

axle shafts. Fits Cub Cadet belt drive garden tractor models 482, 580, 582

Special, 1100, and other makes and models of garden tractors with the Peerless

2300 transaxle. Direct replacement with no machining required. Dimensions:

1" I.D. x 1-3/8" O.D. x 1/4" thickness.

IMPORTANT - Before installing

any new seal, always apply oil or fiber-free grease inside the seal and on

the shaft to keep the rubber lubricated and cool until internal oil can reach

it. With no prior lubrication, the dry rubber will wear away from friction,

causing another oil leak. Do the job right the first time, and it won't have

to be done again for a long time. Replaces Tecumseh/Peerless part # 788008.

Our part # 252277. $10.00 each, plus shipping & handling. |

|

Rear Axle Shaft Oil Seals. Fits IH Cub Cadet garden tractor

models 70, 72, 73, 86, 100, 102, 104, 105, 106, 107, 108, 109, 122, 124,

125, 126, 127, 128, 129, 147, 149, 169, 580, 582, 682, 782, 782D, 784, 800,

882, 982, 984, 986, 1000, 1200, 1210, 1211, 1250, 1450, 1650, including MWSC

Spool axles. Will not fit IH Cub Cadet "Original" garden tractor.

Direct replacement with no machining required. Also fits various other

makes and models of garden tractor with 1" diameter axle shafts and various

garden tiller gearbox tine shaft. Dimensions: 1" I.D. x 1-1/2" O.D. x 1/4"

thickness. IMPORTANT - Before

installing any new seal, always apply oil or fiber-free grease inside the

seal and on the shaft to keep the rubber lubricated and cool until internal

oil can reach it. With no prior lubrication, the dry rubber will wear away

from friction, causing another oil leak. Do the job right the first time,

and it won't have to be done again for a long time. Rear Axle Shaft Oil Seals. Fits IH Cub Cadet garden tractor

models 70, 72, 73, 86, 100, 102, 104, 105, 106, 107, 108, 109, 122, 124,

125, 126, 127, 128, 129, 147, 149, 169, 580, 582, 682, 782, 782D, 784, 800,

882, 982, 984, 986, 1000, 1200, 1210, 1211, 1250, 1450, 1650, including MWSC

Spool axles. Will not fit IH Cub Cadet "Original" garden tractor.

Direct replacement with no machining required. Also fits various other

makes and models of garden tractor with 1" diameter axle shafts and various

garden tiller gearbox tine shaft. Dimensions: 1" I.D. x 1-1/2" O.D. x 1/4"

thickness. IMPORTANT - Before

installing any new seal, always apply oil or fiber-free grease inside the

seal and on the shaft to keep the rubber lubricated and cool until internal

oil can reach it. With no prior lubrication, the dry rubber will wear away

from friction, causing another oil leak. Do the job right the first time,

and it won't have to be done again for a long time.

|

|

Bronze Axle Bushings.

Fits IH Cub Cadet "Original" garden tractor, and IH Cub Cadet garden tractor

models 70, 71, 72, 73, 100, 102 and 122. (All other models of Cub Cadet garden

tractor axle housings originally came with needle bearings.) For "Original"

- hole for Zerk grease fitting will need to

be drill-aligned through bushing after installation. Direct OEM replacement

with no machining required. Dimensions: 1" I.D. x 1.125" O.D. x 1" length.

IMPORTANT: Before reinstalling axles, apply clean motor oil, gear oil

or fiber-free grease inside bushings or on axles for lubrication and prevent

premature wear of the bushings. Replaces discontinued Cub Cadet part

#'s IH-376259-R1, IH-376160-R1 (Cub Cadet "Original" rear axles and clutch

throw-out bushing), and discontinued Cub Cadet part # IH-384664-R2 (models

70, 71, 72, 73, 100, 102 and 122 axle bushing). $9.00/pair, plus shipping

& handling. Bronze Axle Bushings.

Fits IH Cub Cadet "Original" garden tractor, and IH Cub Cadet garden tractor

models 70, 71, 72, 73, 100, 102 and 122. (All other models of Cub Cadet garden

tractor axle housings originally came with needle bearings.) For "Original"

- hole for Zerk grease fitting will need to

be drill-aligned through bushing after installation. Direct OEM replacement

with no machining required. Dimensions: 1" I.D. x 1.125" O.D. x 1" length.

IMPORTANT: Before reinstalling axles, apply clean motor oil, gear oil

or fiber-free grease inside bushings or on axles for lubrication and prevent

premature wear of the bushings. Replaces discontinued Cub Cadet part

#'s IH-376259-R1, IH-376160-R1 (Cub Cadet "Original" rear axles and clutch

throw-out bushing), and discontinued Cub Cadet part # IH-384664-R2 (models

70, 71, 72, 73, 100, 102 and 122 axle bushing). $9.00/pair, plus shipping

& handling.

|

|

Needle-Roller

Axle Bearings to convert axle housings with 1" OEM bronze axle bushings

in IH Cub Cadet garden tractor models 70, 71, 72, 73, 100, 102 and 122, except

the IH Cub Cadet "Original" garden tractor. Reduce friction and free up

horsepower in a high-speed pulling tractor! Made of high quality heat-treated

steel. Dimensions: 1" I.D. x 1.250" (1-1/4") O.D. x 3/4" length. NOTE:

Not a direct replacement for the OEM IH Cub Cadet needle bearings because

these have a smaller outside diameter. Therefore, axle housings with a bronze

bushing will need to be precisely bored to 1.250" to accept these needle

bearings. IMPORTANT: Before reinstalling axles, apply clean motor oil, gear

oil or fiber-free grease inside bearings or on axles for lubrication and

to prevent premature wear of the bearings. $15.00/pair, plus shipping

& handling. Needle-Roller

Axle Bearings to convert axle housings with 1" OEM bronze axle bushings

in IH Cub Cadet garden tractor models 70, 71, 72, 73, 100, 102 and 122, except

the IH Cub Cadet "Original" garden tractor. Reduce friction and free up

horsepower in a high-speed pulling tractor! Made of high quality heat-treated

steel. Dimensions: 1" I.D. x 1.250" (1-1/4") O.D. x 3/4" length. NOTE:

Not a direct replacement for the OEM IH Cub Cadet needle bearings because

these have a smaller outside diameter. Therefore, axle housings with a bronze

bushing will need to be precisely bored to 1.250" to accept these needle

bearings. IMPORTANT: Before reinstalling axles, apply clean motor oil, gear

oil or fiber-free grease inside bearings or on axles for lubrication and

to prevent premature wear of the bearings. $15.00/pair, plus shipping

& handling.

|

|

Bushings / Bearings and Oil Seals to install MTD Cub Cadet

garden tractor 30mm fine spline axles, Midwest Super Cub Axles, or with locking

collars to install Ford Pinto Axles in IH Cub Cadet garden tractor 1" aluminum

or cast iron axle housings. Bushings are more suitable for low-speed tractors,

and needle bearings are suitable for high-speed tractors. Axle housings must

be precision-machined to accept these bushings, bearings and seals. Dimensions

of bushings and bearings: 1-3/16" I.D. x 1.500" O.D. x 1" length. Dimensions

of oil seals: 1-3/16" I.D. x 1.6875" O.D. x 1/4" thickness. No Cub Cadet

garden tractor originally came with these size axle bushings and bearings.

Each replaces MTD Cub Cadet part # 941-3033A (ball bearing) and 941-3020A

(oil seal). IMPORTANT - Before

installing the axles, apply oil or fiber-free grease inside the seal and

on the axle shaft to keep the rubber lubricated and cool until internal oil

can reach it. With no prior lubrication, the dry rubber will wear away from

friction, causing an oil leak. Do the job right the first time, and it won't

have to be done again for a long time. Bushings / Bearings and Oil Seals to install MTD Cub Cadet

garden tractor 30mm fine spline axles, Midwest Super Cub Axles, or with locking

collars to install Ford Pinto Axles in IH Cub Cadet garden tractor 1" aluminum

or cast iron axle housings. Bushings are more suitable for low-speed tractors,

and needle bearings are suitable for high-speed tractors. Axle housings must

be precision-machined to accept these bushings, bearings and seals. Dimensions

of bushings and bearings: 1-3/16" I.D. x 1.500" O.D. x 1" length. Dimensions

of oil seals: 1-3/16" I.D. x 1.6875" O.D. x 1/4" thickness. No Cub Cadet

garden tractor originally came with these size axle bushings and bearings.

Each replaces MTD Cub Cadet part # 941-3033A (ball bearing) and 941-3020A

(oil seal). IMPORTANT - Before

installing the axles, apply oil or fiber-free grease inside the seal and

on the axle shaft to keep the rubber lubricated and cool until internal oil

can reach it. With no prior lubrication, the dry rubber will wear away from

friction, causing an oil leak. Do the job right the first time, and it won't

have to be done again for a long time.

|

|

External Snap

Ring. Fits IH Cub Cadet "Original" Garden Tractor Axles. 1" size. Retains

axle shaft in axle housing. External Snap

Ring. Fits IH Cub Cadet "Original" Garden Tractor Axles. 1" size. Retains

axle shaft in axle housing.

Axle Retaining E-Clip Snap Ring.

Fits IH- and MTD-built Cub Cadet garden tractors with 1" or 30mm fine

spline axles. 17mm size. Fits tractors with serial number 720000 and

above. Axle Retaining E-Clip Snap Ring.

Fits IH- and MTD-built Cub Cadet garden tractors with 1" or 30mm fine

spline axles. 17mm size. Fits tractors with serial number 720000 and

above.

|

|

Rear Axle Shaft

Oil Seal. Fits MTD Cub Cadet garden tractor models 1340, 1440, 1535, 1541,

1641, 1782, 1860, 1861, 1862, 1863, 1864, 1882, 2082, 2084, 2086, 2130, 2135,

2140, 2145, 2146, 2150, 2155, 2160, 2165, 2176, 2182, 2185, 2186, 2206, 2284,

3206, 3208, 3235, 3240, 4814, 4815, 4816, 5234, 5252, 5416, 5418, 5254, 5264,

6284, 7252, 7254, 7264, 7284, 7304, GT3100, XT3-GSX, GT3200, GT3235 and XT3-GSX.

IMPORTANT - Before installing

any new seal, always apply oil or fiber-free grease inside the seal and on

the shaft to keep the rubber lubricated and cool until internal oil can reach

it. With no prior lubrication, the dry rubber will wear away from friction,

causing another oil leak. Do the job right the first time, and it won't have

to be done again for a long time. Rear Axle Shaft

Oil Seal. Fits MTD Cub Cadet garden tractor models 1340, 1440, 1535, 1541,

1641, 1782, 1860, 1861, 1862, 1863, 1864, 1882, 2082, 2084, 2086, 2130, 2135,

2140, 2145, 2146, 2150, 2155, 2160, 2165, 2176, 2182, 2185, 2186, 2206, 2284,

3206, 3208, 3235, 3240, 4814, 4815, 4816, 5234, 5252, 5416, 5418, 5254, 5264,

6284, 7252, 7254, 7264, 7284, 7304, GT3100, XT3-GSX, GT3200, GT3235 and XT3-GSX.

IMPORTANT - Before installing

any new seal, always apply oil or fiber-free grease inside the seal and on

the shaft to keep the rubber lubricated and cool until internal oil can reach

it. With no prior lubrication, the dry rubber will wear away from friction,

causing another oil leak. Do the job right the first time, and it won't have

to be done again for a long time.

|

|

Internal (Wet) Brake Pads/Pucks and Neoprene Rubber O-Ring

Seal. Fits Cub Cadet garden tractor models 70, 71, 72, 73, 100, 102, 104,

105, 122, 123, 124, 125, 580, 582, 680, 682, 782, 784, 800, 1000, 1200, 1210,

1250, 1282, 1450, 1604, 1606, 1650, 1710, 1711 and 1712. IMPORTANT: Before

installing any new oil seal, always apply oil or fiber-free grease inside

the seal and on the shaft to keep the rubber seal lubricated and cool until

internal oil can reach it. With no prior lubrication, the dry rubber will

wear away, causing another oil leak. Do the job right the first time, and

it won't have to be done again. Internal (Wet) Brake Pads/Pucks and Neoprene Rubber O-Ring

Seal. Fits Cub Cadet garden tractor models 70, 71, 72, 73, 100, 102, 104,

105, 122, 123, 124, 125, 580, 582, 680, 682, 782, 784, 800, 1000, 1200, 1210,

1250, 1282, 1450, 1604, 1606, 1650, 1710, 1711 and 1712. IMPORTANT: Before

installing any new oil seal, always apply oil or fiber-free grease inside

the seal and on the shaft to keep the rubber seal lubricated and cool until

internal oil can reach it. With no prior lubrication, the dry rubber will

wear away, causing another oil leak. Do the job right the first time, and

it won't have to be done again.

|

|

External/Axle Disc Brake Liner

Kit. Fits Cub Cadet garden tractor models 106, 107, 127 and 147 with H-H

Products type brake calipers. OEM Cub Cadet part # IH-544835-R91.

$251.85 per set (as shown), plus shipping & handling. External/Axle Disc Brake Liner

Kit. Fits Cub Cadet garden tractor models 106, 107, 127 and 147 with H-H

Products type brake calipers. OEM Cub Cadet part # IH-544835-R91.

$251.85 per set (as shown), plus shipping & handling. |

External/Axle Disc Brake

Pad. Fits IH Cub Cadet garden tractor models 86, 108, 109, 128, 129, 149,

169, 800, 1000, 1200, 1250, 1450 and 1650. NOTE: These are sold each,

and not sold in pairs. Because sometimes one pad on the same axle will wear

more than the other. OEM Cub Cadet part # IH-548122-R2. $75.00

each, plus shipping & handling. External/Axle Disc Brake

Pad. Fits IH Cub Cadet garden tractor models 86, 108, 109, 128, 129, 149,

169, 800, 1000, 1200, 1250, 1450 and 1650. NOTE: These are sold each,

and not sold in pairs. Because sometimes one pad on the same axle will wear

more than the other. OEM Cub Cadet part # IH-548122-R2. $75.00

each, plus shipping & handling. |

Gaskets, Rubber O-Ring Seals and Oil Seals. Fits IH Cub Cadet

"Original" Garden Tractor Transaxle. Prices are subject to change without